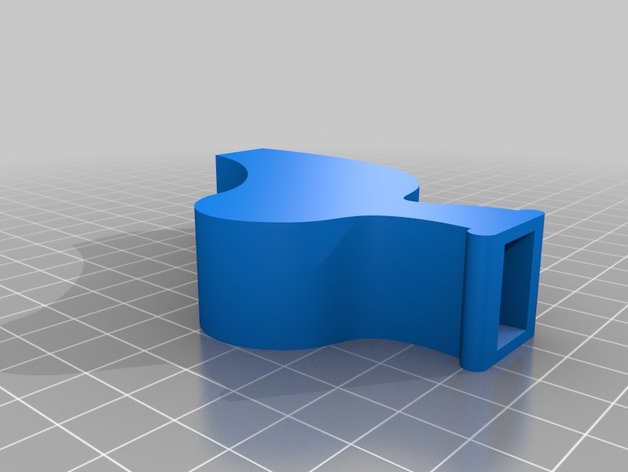

Safety Whistle

thingiverse

Inspired by the Storm Whistle, I created this innovative design. Print the small plastic pellet first. To ensure a smooth printing process, carefully drop the printed pellet into the whistle's circular chamber just as it begins to print. Be patient and wait until the whistle has printed at least 10mm high; note that the base thickness is only 2mm, while the pellet itself measures 8mm in diameter. For optimal results, I recommend printing the pellet using a "spiral vase" mode if your slicer/printer offers this option. If not, simply print with one shell and no infill to produce a hollow pellet perfect for filling the whistle chamber. Contrary to expectations, it's crucial that you print the entire structure without supports; after all, the inside of the whistle must remain completely open and free from any obstructions. This challenging requirement will test your printer's advanced bridging capabilities. Although the bridging and next two layers may appear a bit rough, you should ultimately achieve a high-quality top surface. **Print Settings:** - Rafts: No - Supports: No - Resolution: I've opted for .1mm layers when printing the pellet, while using .25mm layers for the rest of the whistle body. - Infill: For the best results, use no infill for the pellet and a moderate level of infill for the whistle body (40% to be exact). **Designing the Whistle:** Initially, my first prototype proved too wide (as printed) and demanded far more effort than necessary to produce a whistling sound. I rectified these issues in my second attempt by creating a narrower design, carefully calibrating airflow through the mouthpiece, modifying the slot of the barrel chamber, and also incorporating a hollow pea. Although some adjustments were needed, including several slight modifications to the internal layout to achieve a pleasing whistling tone, printing artifacts unfortunately remained an issue. This led to reduced pitch variation from the normally expected pea movement in traditional pea whistles. To address these issues, I plan on redesigning this whistle into multiple parts that can be easily assembled after printing. This should simplify "cleaning up" of any internal imperfections and negate the need for setting an alarm to drop the pellet while the printer is operational.

With this file you will be able to print Safety Whistle with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Safety Whistle.