S3DP KORE Hotend

thingiverse

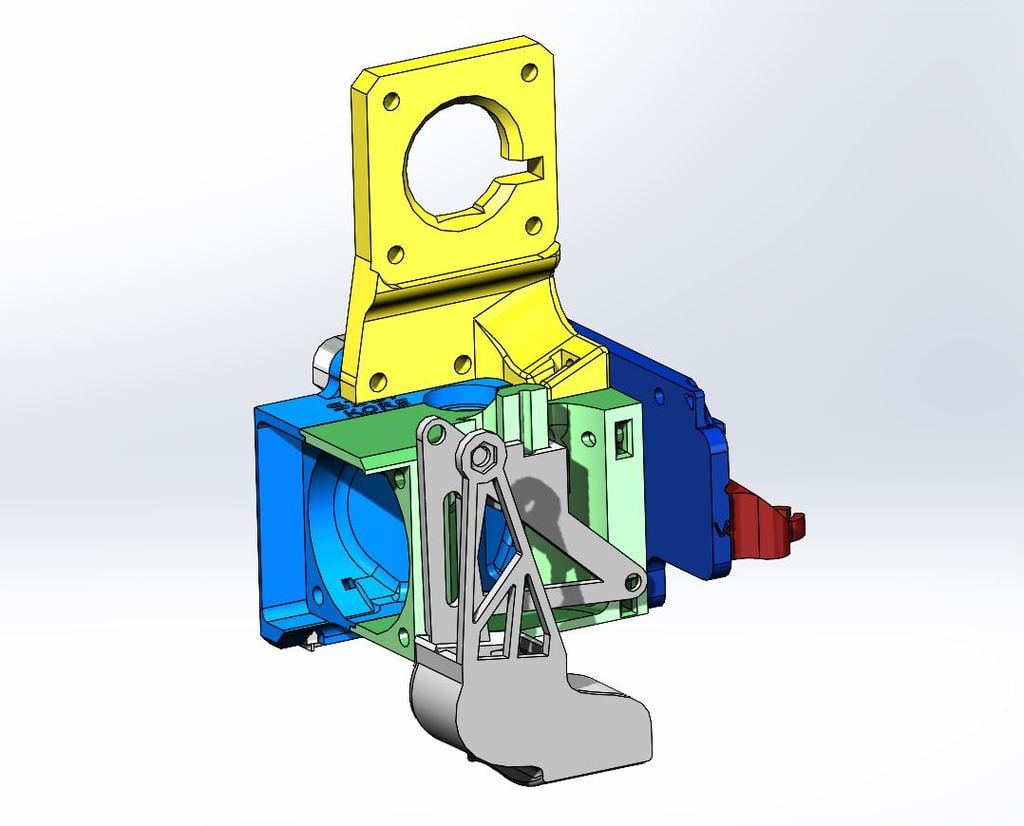

<h1>S3DP KORE V1 Beta</h1> <h2>Simple, Robust, Universal, Expandable Designed for High Heat Applications on Creality Printers</h2> E3Dv6 Style Hotend Mount Version 1.0 www.Syracuse3DPrinting.com Mounts for more printers coming soon **Note this release is currently in testing** Compatible Printers: Ender 3/Ender 3 Pro CR10/CR10 V2*/CR10S Ender 5/Ender 5 Pro/Ender 5 Plus(Pending Testing) *Fully Plug 'n' Play with CR10-V2 OE Hotend and Fans Compatible Hotends Fits most Cylindrical Heatsink "E3D" style hotends, including: E3Dv6 - All Metal, Lite, or Clone E3Dv6 - Volcano or Clone CR10v2 OE Hotend (Mk10 Hybrid with E3Dv6 style heatsink) Files & Contents: S3DPKOREv1.0.stl Rear Shell Front Shell CR10-V2 Mount Ender 3/5/CR10 Mount KOREABLv1.0.stl (Optional) ABL Mounting Adapter Plate BLTouch Adapter KOREPARTCOOLINGv1.0.stl 5015 Cooling Duct 5015 Fan Mount KOREDRIVEv1.0.stl Beta(Optional - Requires KOREABL for use) Direct Drive Adapter Plate BUCKCONV MOUNT.stl For use with S3DP Fan Control Module Recommended Print Material: Polymax-PC Hotend Temperature: 270C Bed: 100-115C Part Cooling Fan: Off Support: None Perimeters: 2 Top Solid Layers: 6 Bottom Solid Layers: 6 Layer Height: .15-.2 Infill: 65%+ Bed Adhesion: 5mm Brim + NANO Polymer Adhesive, Magigoo PC, or similar bed adhesive Speed: Max 50mm/section Alternate Print Materials: PETG, ABS, etc. Some parts may be printed with PLA/PLA+, but note the tolerances of this piece were designed with engineering grade materials in mind. Hardware: The following represents the hardware needed for multiple configurations. You will likely not need all of the hardware listed. You may need different sized hardware based on the equipment you're using, and also may be able to re-use factory hardware. It is highly recommended to purchase a comprehensive kit of metric hex bolts, nuts, and washers. *M2, M3, M4 Button Head Hex Screws: https://www.amazon.com/VIGRUE-Socket-Button-Washers-Assortment/dp/B07MN9X2KN/ref=as_li_ss_tl?crid=1MNPR7D83INB3&dchild=1&keywords=metric+flat+head+screw+assortment&qid=1600789251&sprefix=metric+flat+head,aps,156&sr=8-11&linkCode=sl1&tag=improvisedeng-20&linkId=fef0dc3c05cc4fd351d0d921825f5adf&language=en_US *M2, M3, M4, M5 Flat Head Hex Screws: https://www.amazon.com/VIGRUE-Socket-Button-Washers-Assortment/dp/B07MN9X2KN/ref=as_li_ss_tl?crid=1MNPR7D83INB3&dchild=1&keywords=metric+flat+head+screw+assortment&qid=1600789251&sprefix=metric+flat+head,aps,156&sr=8-11&linkCode=sl1&tag=improvisedeng-20&linkId=fef0dc3c05cc4fd351d0d921825f5adf&language=en_US *M3 Square Nuts: https://www.amazon.com/VIGRUE-Socket-Button-Washers-Assortment/dp/B07MN9X2KN/ref=as_li_ss_tl?crid=1MNPR7D83INB3&dchild=1&keywords=metric+flat+head+screw+assortment&qid=1600789251&sprefix=metric+flat+head,aps,156&sr=8-11&linkCode=sl1&tag=improvisedeng-20&linkId=fef0dc3c05cc4fd351d0d921825f5adf&language=en_US *M4 Square Nuts: https://www.amazon.com/VIGRUE-Socket-Button-Washers-Assortment/dp/B07MN9X2KN/ref=as_li_ss_tl?crid=1MNPR7D83INB3&dchild=1&keywords=metric+flat+head+screw+assortment&qid=1600789251&sprefix=metric+flat+head,aps,156&sr=8-11&linkCode=sl1&tag=improvisedeng-20&linkId=fef0dc3c05cc4fd351d0d921825f5adf&language=en_US [Note: Square nuts generally come in 2 thicknesses, this part is designed to use the thinner variant] M3 Square Nuts (2mm Thickness): x13 M4 Square Nuts (2mm Thickness): x2 M3 Hex Nuts: x8 M3 x 16mm Flat Head Bolts: x8 M3 x 20mm Flat Head Bolts: x4 M3 x 16mm Button or Socket Head Bolts: x14 M4 x 30mm Flat, Button, or Socket Head Bolts: x2 M3 x 25mm Flathead Bolts: x3 M3 x 10mm Button or Socket Head Bolts: x2 Single Fan Cooling Mode: 1x 4010/4020 40mm Cooling Fan - 1x 5015 Part Cooling Fan Install fans into appropriate locations on the S3DP mount and print your favorite cooling fan cover. CR10-V2 Notes: Existing fans, hardware, and fan cover can be re-used. Dual Cooling Fan Mode (WITHOUT S3DP KORE Command Module): Remove OE cooling fan Install (2) 4010 or 4020 Cooling fans on either side of the mount as indicated (Fans should be similar specifications) Fans should be installed in opposite directions (One push, One pull) to flow air over the hotend heatsink Wire pans in parallel and connect to the factory fan wiring. For best results, use solder and heatshrink for connections. Dual Cooling Fan Mode (WITH S3DP KORE Command Module): Remove OE cooling fan Cut connections to OE Fan close to fan and connect wires to corresponding location on S3DP Fan Control Module Install (2) 4010 or 4020 Cooling fans on either side of the mount as indicated (Fans should be similar specification). 12V Noctua or similar fans can be used if a buck converter is fitted to the Control Module. Fans should be installed in opposite directions (One push, One pull) to flow air over the hotend heatsink Connect fans to the S3DP Fan Control Module using the supplied connectors. Verify polarity per instructions provided with the control module. Part Cooling Fan: Use OE or other 5015 Blower Fan installed per the diagram, and adjust height to match nozzle height. When height is set, use M3x25mm Bolt inserted from the top of the slider mount to secure the location. Assembly instructions Remove factory hotend mount and hardware Remove brim, and deburr part as necessary. Use a small screwdriver or drill bit as needed to clear any stringing from bolt holes and nut recesses. Insert M3 and M4 square nuts throughout parts as needed before assembly. M3 nuts indicated by hexagonal holes may need to be heat-set depending on print results. Hotend may be mounted into the assembly before OR after unit is mounted to the X-Gantry, but it is recommended to install the clamshell assembly in one piece for easier routing of wiring. For CR10-V2 (Using CR10-V2 Mounting Bracket) Use 3x M3x16 Socket or Button Head Bolts to secure the assembly to the X-Gantry using the factory mounting holes, from the rear. Bolts should go through the mounting bracket and into the captured square nuts. [Optional] Use an M3 x 10 Button/Socket head bolt to secure the top left ear to the captured M3 hex nut in the mounting bracket. Make sure unit is level to bed before tightening. For Ender 3/5/CR10 Style: (Using Ender 3 Mounting Bracket) First mount the Ender3 mounting bracket to the X-gantry using M3 x 10 Flathead bolts into the factory heat-shield mounting locations. Assembly should locate onto original hotend bosses, but no hardware is used here. Use 2x M3 x 10 Button/Socket head bolt to secure the top ears to the captured M3 hex nuts in the mounting bracket. Use 2x M3 x 10 Taper head bolts to secure the bottom of the mounting bracket to the captured M3 Square nuts in the back of the clamshell (From the rear) ABL/BLTouch Installation *Due to the low profile adjustable mounting system, it is highly recommended to print this part from an engineering grade material like PC BLTouch Mounting Plate installs on the right side of the hot end, with or without secondary cooling fan. For BLTouch, use 2x M3 nuts inserted into the top of the mount. Attach the BLTouch using 2x M3 x 10mm Button/Socket head bolts from the bottom. Carefully slide the BLTouch adapter onto the mounting plate. Move the slider until preset holes are aligned "V" hole is for Volcano style hotend. Other hole is for standard hotend. Secure the slide using a single M2 bolt or set screw once aligned. If not using pre-set alignments, use a single M3x20mm bolt from the top to secure the slide anywhere along the range. BLTouch Offsets: (Distance to Nozzle) X-Axis: + 39.5mm Y-Axis: - 37.2mm For Direct Drive Installation: (Using Direct Drive Mounting Bracket) This bracket re-uses the factory extruder and stepper motor to allow you to modify your printer for direct-drive extrusion. You may opt to use an upgraded aluminum, or aluminum dual-gear extruder meant for an Ender 3/CR10 printer. You may also opt to use a smaller pancake-style stepper motor This bracket must be used in conjunction with the ABL Mounting bracket. (ABL is not necessary) Place the bracket on the top of the completed assembly and secure using 3x M3 x 16 Button/Socket head bolts. 2 bolts to the top ears, and 1 to the ABL mounting bracket. Washers are recommended. Use a small piece of bowden tubing to fill the gap between the fittings. The length of this may vary depending on extruder design. Secure the extruder and stepper motor together onto the mounting plate using 4x M3 x 16 bolts. Longer bolts may be needed depending on extruder design. Re-route or extend extruder wiring to the new extruder location. Make appropriate adjustments in the printer firmware and slicer as needed for the change to direct drive. The new assembly will be heavier with the extruder on the gantry. Acceleration and speeds should be de-rated to compensate. Retraction should be adjusted for direct drive to <1mm, but this may need fine tuning. If changing the extruder gear size, be sure to calibrate the extruder E-steps. For additional support, visit the Thingiverse page at Syracuse3DPrinting, or www.Syracuse3DPrinting.com All modifications are to be done at your own risk.

With this file you will be able to print S3DP KORE Hotend with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on S3DP KORE Hotend.