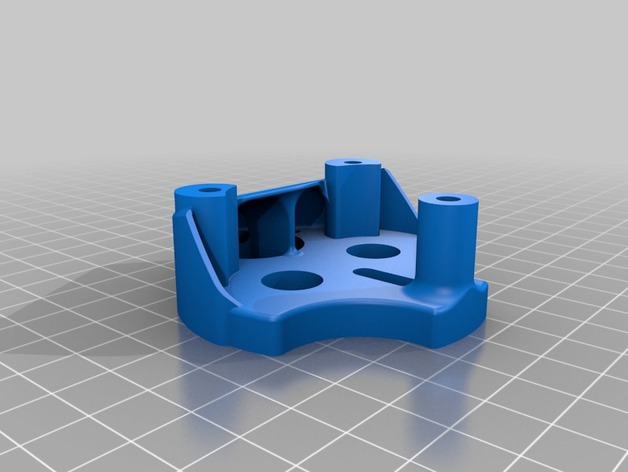

Rostock Max Dual Extruder Mount

thingiverse

Adjustments were made in measurements to account for ABS shrinkage post-printing. The nozzle delta in the "V2_mod" or "old Skully" version ranges from X +/- 13mm with more substantial notches for heater and thermistor wires. Version "V3," also known as "crimson hun," includes a cooling solution for PEEK printing, requiring two 25x20mm high-power fans for models over 25x10mm. The latest version, "V4" or "why-didn't-I-think-about-this-earlier," integrates the spacers and may need adjustments to Repetier Firmware (0.83) for fan control. A potential issue with effector plate swiveling is addressed by tweaking the "END_EFFECTOR_HORIZONTAL_OFFSET" in Repetier's configuration. A future version, "V5," may incorporate a 40mm fan mount/duct for PLA cooling. Printing recommendations include using ABS at .15 layer height with reduced speed, and potentially sanding spacers to achieve uniform height depending on printer calibration and material used. Extruder holes should be tight-fitting; if there is play, aluminum foil can be wrapped around the extruders. The main hole of the effector plate requires sanding for adequate space between the extruder hot end and effector material. Hot ends are plugged into the mounted holes with shims for vertical alignment, followed by assembly of fans using M2 x 30mm screws and self-locking nuts. Thermistor and heater cartridge cables, as well as fan wires, should be secured with zip ties on the elongated hole in the mount's center. Another method for vertical hot end alignment is using heat-resistant rubber edge protectors between the stop plate and mount. Suggestions for alternative installation methods are welcomed.

With this file you will be able to print Rostock Max Dual Extruder Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Rostock Max Dual Extruder Mount.