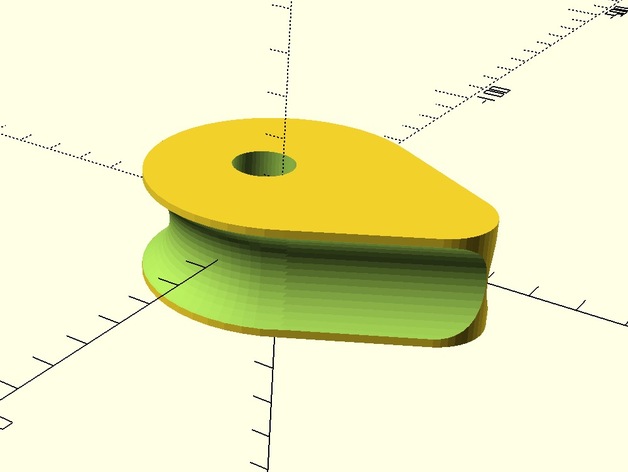

Rope Thimble

thingiverse

I designed a custom thimble to protect the rope eye of my anchor mooring from chafe and damage caused by barnacles and corroded shackles. The mooring rope is prone to wear over time, which can compromise the entire anchor line. To create this thimble, I chose to print it in nylon for added strength or ABS for cost savings. The number of layers and fill percentage directly impact the overall strength of the printed part. I decided on five layers with a 30% infill for my initial design, which worked well for a one-inch rope thimble that weighed approximately 59 grams. To optimize economy, I hollowed out the low-stress area of the thimble and used internal support in the print settings. When printing this part, it's essential to set the debug mode to true to inspect any hollowed-out areas before continuing with the print job. Additionally, I found it helpful to add a frame around the throat of the thimble for easier removal after printing. This was achieved by using rafting and then cutting out the frame with a bandsaw. The printer settings used were as follows: LulzBot TAZ 6, medium resolution, and a combination of rafts and supports enabled.

With this file you will be able to print Rope Thimble with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Rope Thimble.