Rocket Science -- Canned Air Rocket

pinshape

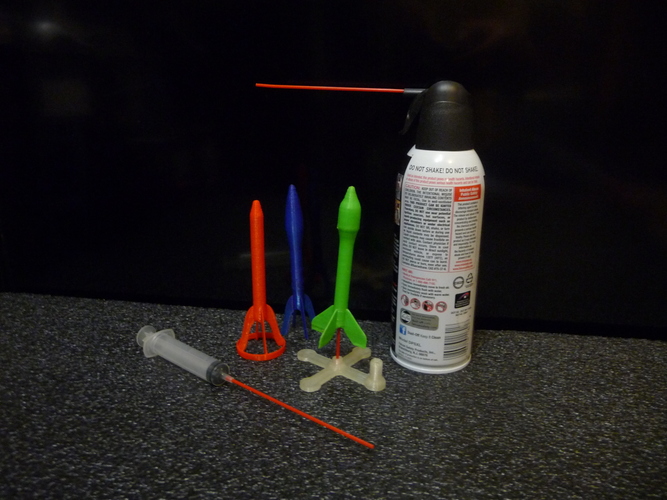

To fly the rockets, you will need a syringe and the red tube from a can of compressed air to inject a little bit of water into the rocket. You have to carefully drill out the tip of your syringe by hand to get the tube to fit the tip of the syringe. Put the tube back on the can, and point it upward. Drop the rocket down on the tube and pull the trigger quickly. I used Dustoff canned air as a propellant. The tube that comes with this brand fits a 3mm nozzle perfectly. There are other brands that have a larger tube. If that is what you are going to use, you will have to design a rocket with a larger diameter nozzle. There are two types of rockets here. One type has the fins built into the rocket with the fuselage elevated. The other has slots at the tail end of the rocket for the fins. I recommend printing a couple of extra fins in case they shear off when the rocket lands on a hard surface. I filled mine as much as half full of water, and was able to get about six seconds of flight time. When you pull the trigger on the canned air, you have to pull it quick. You want the propellant injected into the rocket suddenly. Also, I think that having the can a little bit inverted works better because some of the propellant is injected in liquid form. Getting the right amount of water is important. Maybe 1/3 to 1/2 full. It is something to experiment with. You can use a syringe to measure the water you put in it to determine the best amount. If you print in a translucent plastic, you can see the water level. You should be able to get this to fly over the treetops. Don't fly it around cars. It might come down and make a dent. An open grassy area is good. Decided to test the limits. I've built a launcher that I can connect to my air compressor. I have a solenoid valve that can handle up to 145 lbs of pressure. I'm not much into photography, so have repurposed my tripod. I'm using standard air line fittings, L bracket, and have made a plastic adapter (stl included) to adapt my launch tube to the inside of one of the fittings. The tripod, and compressor pressure regulator make it possible to more precisely measure rocket performance. I've constructed a launch control box on a long wire, and successfully launched rockets using 145 lbs of pressure. I would like to try a higher pressure, and maybe I can do that if I can find a higher pressure solenoid valve. Initially I had been concerned that 145 lbs of pressure might explode the rocket, but after testing, it appears that there is no chance of that.

With this file you will be able to print Rocket Science -- Canned Air Rocket with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Rocket Science -- Canned Air Rocket.