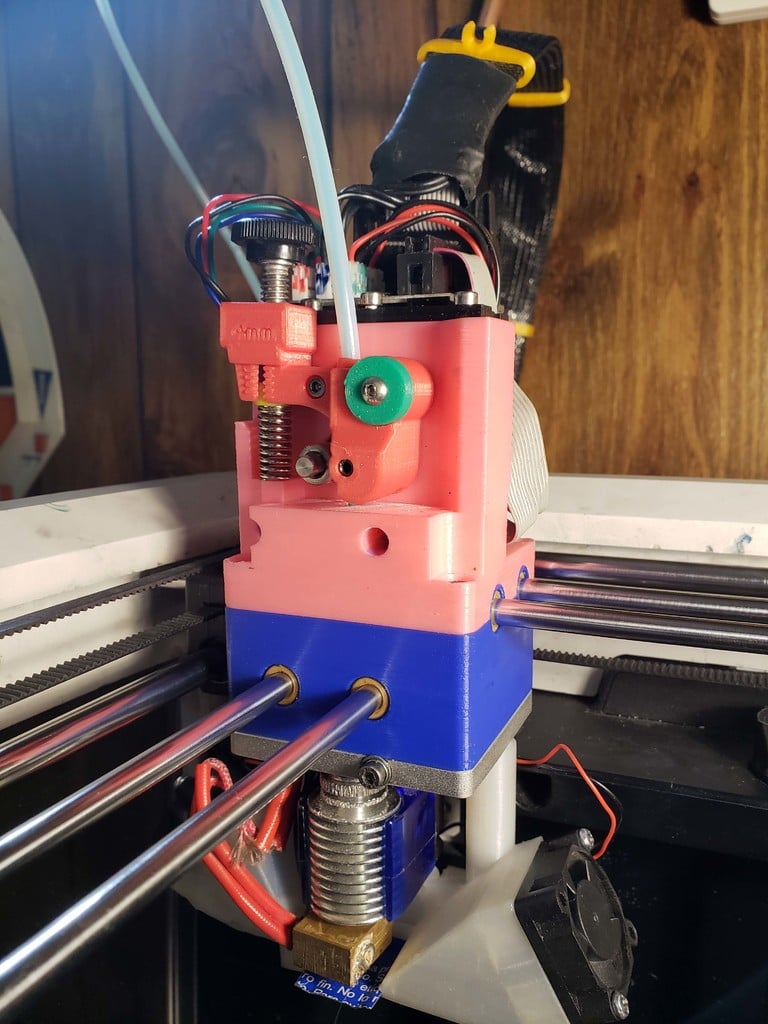

Robo R2 Print Head Plastics

thingiverse

The primary function of these plastics is to enhance the print output. To minimize ghosting, the top plastic has been reinforced to reduce flexing during extrusion starts/stops and changes in direction. The arm features a large plastic bearing that secures the stepper on the upper right side, making mounting more rigid. The arm also includes variable spring pressure, which I found to be essential for preventing heat creep and improving finish, especially when using soft PLA. To achieve this, less pressure is required. The bushings situated on either side of the bottom plastic provide a long bearing that significantly reduces play in the assembly. This ensures precise movement and stability during printing. I have utilized a pancake stepper to reduce weight and enable faster print speeds by allowing the print heat to run at higher temperatures. However, you can use the existing stepper if preferred. When installing the stepper mounting screws, blue loctite is recommended as it may not be possible to secure them without damaging the stepper. Any screw that is not properly secured will come loose over time. This release has overlap with other updates. The individual parts are designed to work seamlessly with the existing Robo plastic, but they are intended to be used together for optimal performance. To install the bronze bushings, lightly coat a 6mm rod with oil and pass it through a bushing to prevent epoxy from sticking to its interior. Then, apply quick-set epoxy to the bushing and press it into the plastic. Repeat this process for both sides of the plastic. Next, insert the 6mm rod coated with oil through the bushings and move it around until it slides freely. Remove any excess epoxy and repeat the process for all four pairs. Reassemble the parts carefully, using the alignment tools provided by Robo to ensure proper alignment. I have assembled four units, but one of them was stiff due to improper alignment. It's essential to use the Robo alignment tool as this setup has minimal play when completed. If the assembly becomes too tight, heat the 6mm rods in the center of the carriage and then move the print head over the heated rods. The PLA will soften, and the bushings will perfectly center. However, ensure that you align the carriage first, as improper alignment may result in a stiff assembly. To maintain optimal performance, I recommend oiling the bronze bushing regularly. To do this, run a 5-hour print without filament loaded to remove any roughness from the bushings and allow them to move freely. I strongly advise switching to ground and hardened rods if you haven't already done so. This will significantly improve assembly and disassembly processes. The required parts include: Any 1" or longer 1/4-40 bolt will work in the arm, but I prefer the look of this thumb screw. M3-.5 x 25 socket head screws for mounting the arm to the stepper (x1 piece) M3-.5 x10 socket head screws for mounting the stepper (x2 pieces) M3-.5 x8 flat head socket screws for mounting the stepper (x1 piece) M3-.5 x(10-20) socket head screws for mounting PCB's to the bottom (x2 pieces) M3-.5 x(10-20) socket head screws for mounting PCB's plate to the top (x3 pieces) m4-.7 x 20 socket head or set screw for mounting bearing to arm m2.5 x 10 for the arm, although I'm unsure of its purpose as it was present in the original design A 4mm x12 mm x 4mm sealed bearing for the arm to press against filament You can find Pitsco Education 40227 Tetrix Prime 6 mm Id x 8 mm od Bronze Bushing (Pack of 12) at Amazon. https://www.amazon.com/gp/product/B01N9SBEHT/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

With this file you will be able to print Robo R2 Print Head Plastics with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Robo R2 Print Head Plastics.