RIP 602 - Prusa MK3 Extruder Upgrade (R3 edit)

thingiverse

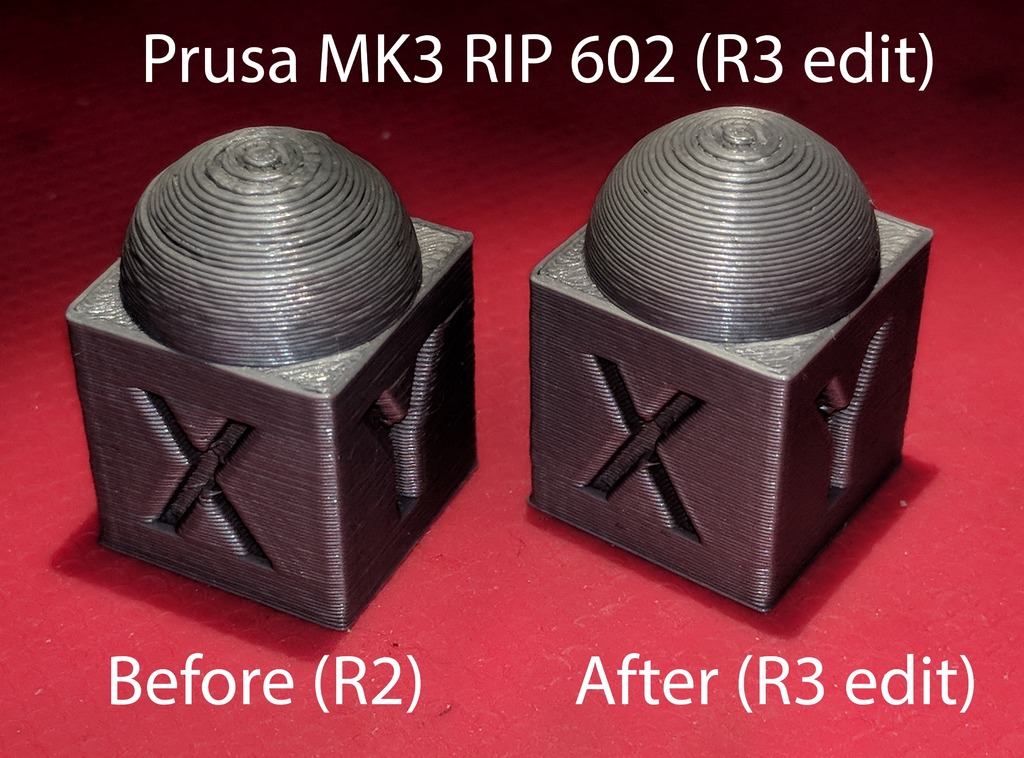

Issue 602 continues to exhibit excessive inconsistent extrusion on MK3 and MK2.5, resulting in a noticeable basket weave pattern on all prints or complete failure to extrude after retracting or doing circles. This issue is particularly pronounced at layer heights of 0.3mm and when printing round objects. User-to-user variation with Issue 602 exists, and many similar-looking results can be easily mistaken for this specific problem. Over-extrusion, in particular, can be a challenging symptom to distinguish from the Issue 602 issue. The goal was to replicate all aspects of the MK2 extruder while incorporating MK3 parts, ensuring seamless integration. Airflow optimization: Noctua airflow path has been significantly widened to mitigate funneling air like in stock configurations. The cone shape previously caused turbulence; now air flows freely with minimal resistance and potentially expels more hot air. The venturi hole was removed as it created unwanted turbulence in addition to the existing cone-shaped turbulence. A smaller, better-designed pathway for filament replaces the PTFE bit, allowing the filament sensor to function normally. The hole was filled to view the filament sensor that requires a tiny print to block light; this is no longer necessary. Tension adjustments: Research and CAD work indicate that the gear teeth are about 25% into the filament pathway on each side for the MK2 extruder. In contrast, the MK2 hobbed gear teeth are 75% into the filament pathway, with the idle bearing pushing the other side. The MK3 configuration does not compensate tension in this manner; its gears are positioned at an equal distance from the filament path. The MK3's center-located gears should provide optimal tension. To match the MK2's tension compensation, stepper and gear offsets of 0.25mm were implemented, which is halfway to a full 0.5mm offset suggested by another user experiencing this issue. This adjustment increases tension on the steppers' gear and allows for additional tension with the idler. The idler direction was inverted so it flips down instead of up like in the MK2 configuration. The updated idler design features flush sides, accommodating a 2cm-long metal rod; however, be cautious when inserting. I hope these adjustments bring improvement to your prints. While this may not completely eliminate Issue 602, it is a significant improvement over R2 extruder parts.

With this file you will be able to print RIP 602 - Prusa MK3 Extruder Upgrade (R3 edit) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RIP 602 - Prusa MK3 Extruder Upgrade (R3 edit).