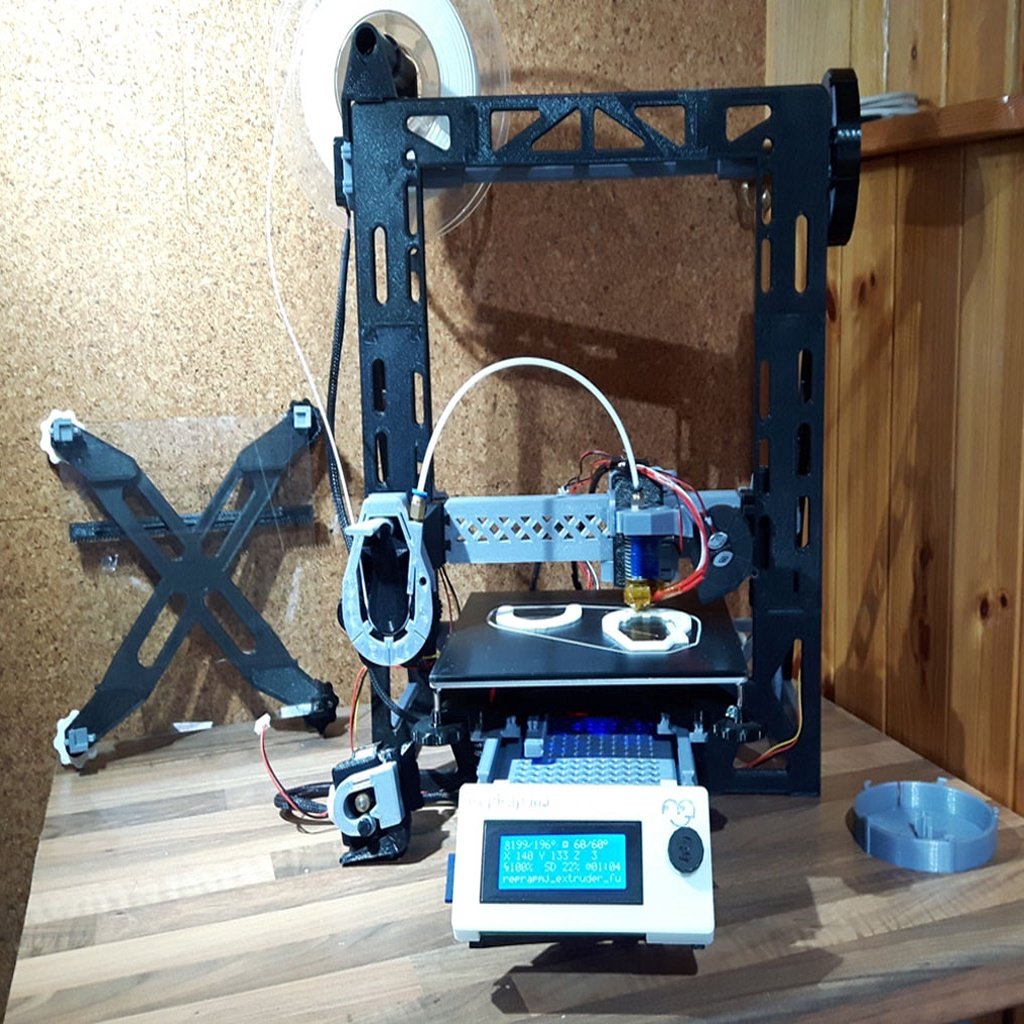

ReprapMJ 3D Printed “Prusa Style” Nylon Capable and Easy to Use 3D Printer with Full 200mm Build Size but Small Footprint reprapmj

thingiverse

ReprapMJ is a true reprap that can print itself almost completely. The basic version has just one hardware part count - the print bed. One NEMA motor is used for the Z axis, so electronic parts are reduced too. Here's the basic printer's parts list: 1 220mmx220mmx3mm sheet of glass or phenolic board (phenolic for printing nylon). 4 NEMA17 motors with wiring (40mm long fit standard clamps but scads are added to modify clamps for other NEMA17 motors). 3 Mechanical endstop switches with wiring. 1 Motherboard (I use the MKS Gen L). 1 Hotend (I use a J7 which comes complete including a fan, bowden tube and wiring). 1 150w 12v Power Supply. Everything else is printed - and I mean everything else! You can add a Heated Bed, LCD/SD Card and a nylon capable Extruder: 1 220x220 Heated bed with wiring (I use the Anycubic Ultrabase). 4 Springs for the above. 1 LCD 2004 with SD Card reader (my favourite screen). An alternative extruder needs: 1 Brass knurled gear. 1 U604 bearing. Everything else is printed - and I mean everything else! The basic version works amazingly well, aiming to be almost completely printable. Print quality is high and it can make a working version of itself. ReprapMJ has a build volume of 200mm on the X axis, 210mm on Y, and 170mm on Z. It's very neat with a small footprint. Rack and pinions are used for all axes. With no belts, maintenance is more convenient and easy. The Z axis uses one NEMA motor and a PLA printed counter balance spring to carry the weight of the X carriage. The X carriage can be raised and lowered by hand without needing a computer or control interface. The build plate assembly can easily be removed and swapped for a different bed (I typically swap between a heated Ultrabase for PLA, ABS, PETG etc etc and a non-heated plain sheet of Phenolic board for Nylon). The standard J7 hotend works with nylons such as Taulman Bridge or Alloy 910 but there's a version available which is rated to 300 degrees if needed. There's a fully printed extruder that works well with PLA. However, it doesn't grip nylon sufficiently and an optional extruder can be used which needs two hardware parts. A document is attached including a copy of the text along with a full list of parts and some assembly instructions. They are brief at the moment but I will update them when I have time. So far, I am the only person who has printed a ReprapMJ. I've used an Ender3pro, a TronxyX3 and earlier versions of ReprapMJ, all giving consistent results. However, some printers may differ and fine tuning of print settings might be necessary. I'll appreciate any feedback and comments.

With this file you will be able to print ReprapMJ 3D Printed “Prusa Style” Nylon Capable and Easy to Use 3D Printer with Full 200mm Build Size but Small Footprint reprapmj with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on ReprapMJ 3D Printed “Prusa Style” Nylon Capable and Easy to Use 3D Printer with Full 200mm Build Size but Small Footprint reprapmj.