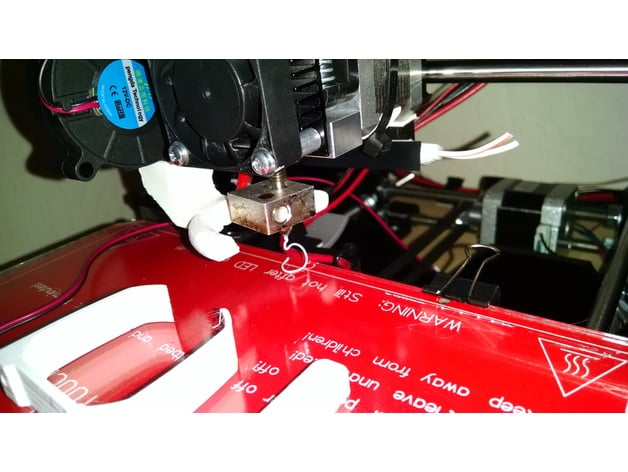

RepRapGuru Cooler Kit

thingiverse

I learned the hard way that when printing ABS, turn off the fan completely. It was causing part curl at the end of the print. --- Update --- I installed a 10uf capacitor across the (+) (-) terminals and it significantly reduced the motor noise. For kicks, I tried a 100uf cap, and lost the ability to adjust the fan speed, it's like Ramps wanted to push the fan 100% on with no speed control. So somewhere between 10uf and less than 100uf should be perfect. A picture is added. This is a mashup of three existing "things", using parts from which as a print cooler that works well with the RepRapGuru hot end assembly. Print these three things and add to it a 5015 12v blower fan. I zip-tied my clip to the extruder motor for extra security. Note: this produces a lot of airflow... enough to affect print bed temp and make the printer work harder to keep the print head heated. You'll want to experiment with the fan % in your Slic3r config. I wonder if a 24v fan would work better since it would have lower output when fed 12v. Driving the blower motor at ~30% works nice, but it's really loud. I'm going to put a 10uf capacitor across the fan power leads to try and quiet it down. PWM is so noisy.

With this file you will be able to print RepRapGuru Cooler Kit with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RepRapGuru Cooler Kit.