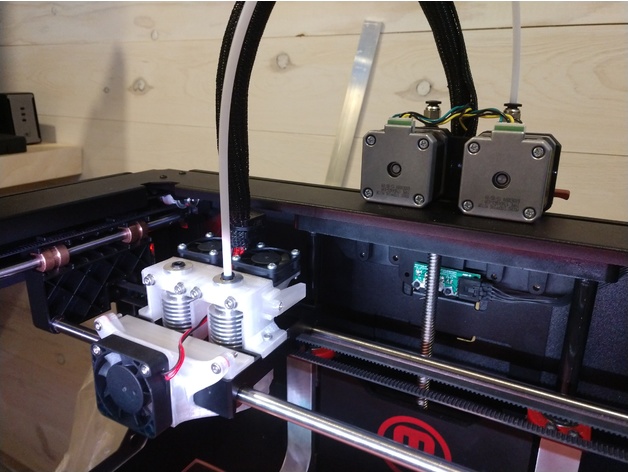

Replicator 2x E3D-v6 Upgrade

thingiverse

UPDATE 10-7-2019: New files uploaded. Improved tolerances for "right off-the bed" use make a huge difference. I highly recommend using Poly-Carbonate for this print, but my original ABS one lasted many prints and performed quite well. UPDATE 6-23-2019: Added V2 files with rounded edges for a sleeker look. Modified fan ducts to allow for more space to run wires. Went back to the old design without extra recess for nozzle leveling. Putting a small shim under one side where the holder bolts to the carriage seems to work just fine. UPDATE 3-11-2017: Added "Hotend_Holder_adjustable.stl" and "left_mount.stl." Now you can level the hotends to the bed! The recesses for the left hotend have been deepened to allow for slight vertical travel up and down. Turn that old POS Replicator 2x into a powerful and functional printer by upgrading your extruders with an E3D-v6 kit. This modification/upgrade will improve printing performance tremendously and will allow the use of higher temp printing materials like nylon and Poly-Carbonate! Moving the extruder motors off of the x-carriage reduces weight and drag, producing more precise movements and ultimately better prints. No physical modification of the x-carriage is required! I printed the original ABS one (the red one in pics) on a Huxley, then used it to print the new PC one (the translucent one in pics). Rep 2x Poly-Carbonate Settings: Extruder temp: 270C Bed Temp: 112C General Speed: 28 mm/s Infill: 100% I used Kapton Tape with a PVA Glue stick on top with a glass bed. Active Cooling Duct found here: https://www.thingiverse.com/thing:3756027 Parts: 2x E3Dv6 24v 1.75mm Kit (w Bowden add-on) see note at bottom.....! 2x 4mm Push In Joint Pneumatic Connector Quick Fittings (5mm Male Thread) 4x M3 x 25 Hex-Head Socket Cap Screws 4x M3 Washers Part 1: Extruder Holder Assembly 1. Attach the fans to the fan ducts; keep track of left and right. 2. Snap/push on fan ducts to the heatsinks......when mounted correctly the ducts angle away from each other 3. Drop two M3 Nylocks into the recesses of the holder; 4. Mount the holder complete with fan ducts to the Rep2x's x-carriage using two M3 x 12 screws Part 2: Hotend Holder Assembly 1. Using screws from the kit, attach the fans to the fan ducts. 2. Keep track of left and right. 3. Snap/push on fan ducts to the heatsinks......when mounted correctly the ducts angle away from each other 4. Drop two M3 Nylocks into the recesses of the holder; 5. Mount the holder complete with fan ducts to the Rep2x's x-carriage using two M3 x 12 screws Important Notes: * You cannot use thermisters with the rep2x.....you need a k-type thermocouple. * There are two different versions of the e3dv6 kits; the older kits come with thermisters and have a threaded mount. You can use the factory thermocouples from your rep2x in this case. The newer kits have a cartridge sensor that is held by a set screw; make sure you get the K-type cartridge. * There are two files for the extruder holder, one is for aluminum extruders (alum_ext.stl) and one is for the factory MB extruders (makerbot_ext.stl) * You can get the aluminum extruders here:http://www.ebay.com/itm/Makerbot-Replicator-2X-Extruder-Upgrade-Filament-Drive-Build-Plate-Glass-/141896285178?hash=item2109ad7bfa:g:Mi8AAOSwwbdWMSx8 * Only the ducts need supports when printing Print Settings: Printer Brand: RepRap Printer: Huxley Rafts: No Supports: Yes Resolution: .2 Infill: 100% Notes: ABS

With this file you will be able to print Replicator 2x E3D-v6 Upgrade with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Replicator 2x E3D-v6 Upgrade.