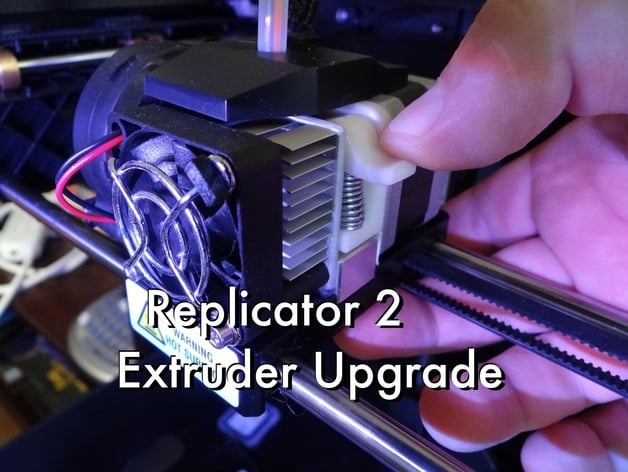

Replicator 2 Extruder Upgrade

thingiverse

Here's my take on your text: This upgrade for MakerBot's Replicator 2 replaces the stock Delrin plunger with a pinch roller, offering increased filament drive force. The design uses an adjustable arm that pivots on a low-friction pin, and requires a 3/8" x 1/1-8" x 0.041" spring, a 623Z bearing, and M3 x 10mm counter-sunk hex head screws for installation. The upgrade process involves disassembling the extruder, assembling the new parts, and reinstalling the extruder on the printer. The author provides detailed instructions, including a list of required components and their sources, along with tips for troubleshooting and maintaining the upgraded extruder. The author notes that the Delrin plunger drive in the stock Replicator 2 is prone to failure due to insufficient spring travel and inability to accommodate filament diameter variations. The upgrade aims to provide a more reliable and consistent drive force for 3D printing. The author also provides a rationale for the design, citing his professional experience as a product designer and outlining the challenges faced with the stock extruder. The upgrade parts are printed using a MakerBot Replicator 2 and PLA filament, with specific print settings provided. The author recommends printing two pinch roller pins to ream out the holes in the arm, and suggests printing the parts slightly leaner than usual for better fit. The spring is available from Home Depot, True Value hardware stores, Amazon, eBay, and Bunnings Hardware Stores in Australia, or can be ordered online from Century Spring Corp. and Industrial Springs. The bearing can be found on eBay, at Fastenal stores in the US, or purchased from BilbyCNC in Australia. The upgrade process involves unloading filament, turning off the printer, disassembling the extruder, assembling the new parts, and reinstalling the extruder with the upgraded components. A gasket made from card can be used to isolate the stepper motor from the cooling block in hot climates. Loading and unloading filament is done manually by adjusting pinch pressure with the thumb. The author also provides tips for optimizing packing density and filament diameter in skeinforge profiles, and suggests applying a light film of vegetable oil to the filament feed tube to reduce friction. The author concludes by sharing a remedial action for softened PLA arm due to overheating, involving re-shaping it with hot water and reinstalling it on the stepper motor.

With this file you will be able to print Replicator 2 Extruder Upgrade with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Replicator 2 Extruder Upgrade.