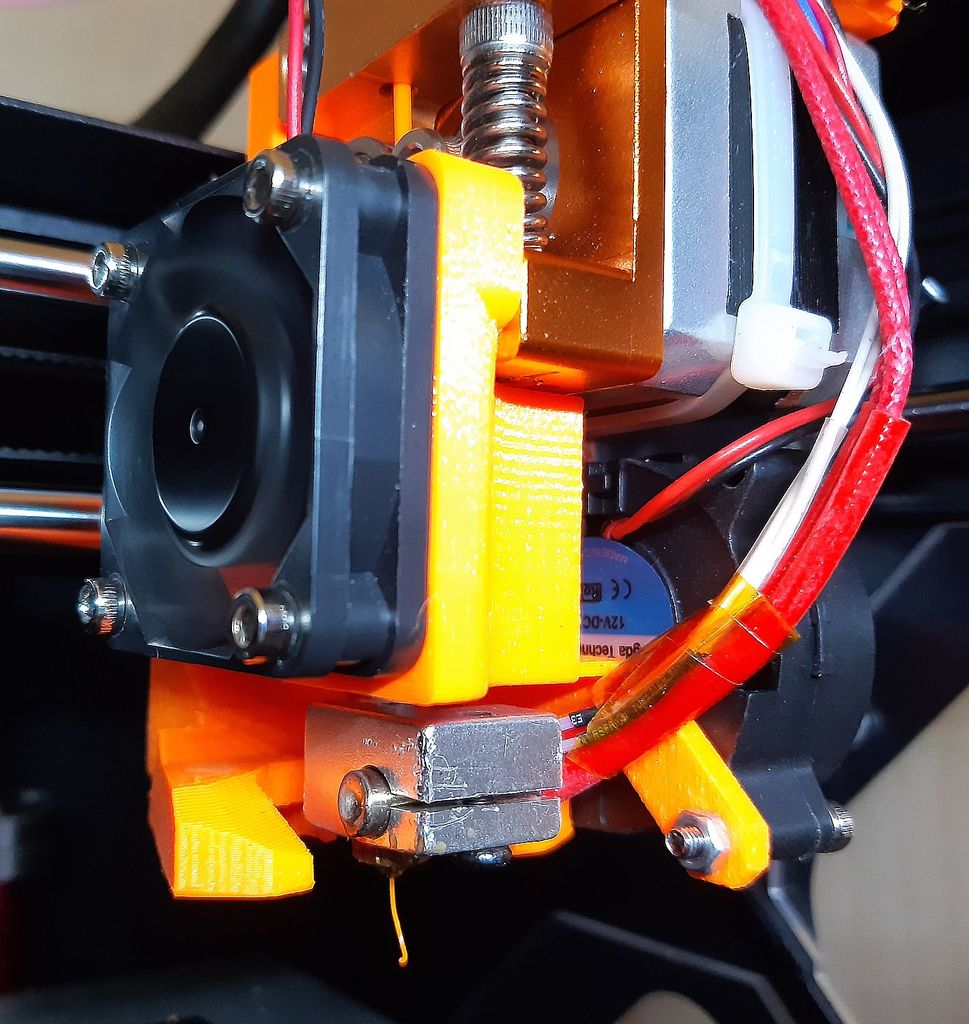

Renkforce RF100XL extruder, based on E3D and MK8

thingiverse

Hi, Here is the extruder for Renkforce RF100XL based on modified MK8 and E3D. Concerning the air duct - I used the original Prusa MK3 part (model is available for free on Prusa webpage). Forgive me this brief description - I promise to prepare more detailed tutorial. As for now - let the pictures speak. Among the uploaded files, you can find the STL with whole assembly (however some parts: both fans, NEMA stepper motor and MK8 extruder have been downloaded from the Grabcad webpage). The remaining parts have been designed by me using Freecad 0.18 with A2Plus extension. Components were printed using PET-G: first layer 0.4 mm thick, the rest - 0.2 mm. I think kind of modified PLA (more immune to high temperatures) will work for you as well. Actually I'm quite happy with the results I've obtained with my Renkforce. Don't hesitate and ask me if you need some help. Suggestions and complaints are also welcome :). Some important notes: MK8 was slightly modified: I used smaller gear, with diameter of 7.7 mm instead of 11 mm, for bigger pushing force. Due to the mod, the hole for the hotend must be 1.65 mm shifted in the direction of the stepper motor shaft. If, in your case, the force is high enough, then there is no need to modify MK8, however the part called "duct" for directing the air around radiator will not fit. The kit with E3D contains small fan and sort of fancy plastic part to install it on radiator. Instead, I used bigger fan which can also blow some air on the motor to keep it cool. Motor overheating often happened to me before. I cut the part of the E3D radiator leaving just the center part with the cooling fins. The whole hotend and radiator are attached to extruder by two standard M6 pipes (with PTFE inside) connected in series. I've polished the end of M6 pipe (on the side of gear and bearing) to leave there as little space as possible. This will, hopefully, preserve the filament form bending. My intention is to be able to print with rubber. The air tunnel for cooling the filament contains support. This shows the orientation of printing as well. You've got to remove it before assembling. The stepper motor and the extruder, except air duct for filament cooling, are attached and positioned to the main holder by one screw (which must be previously removed from the motor) and the cable tie. Cheers Fimek

With this file you will be able to print Renkforce RF100XL extruder, based on E3D and MK8 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Renkforce RF100XL extruder, based on E3D and MK8.