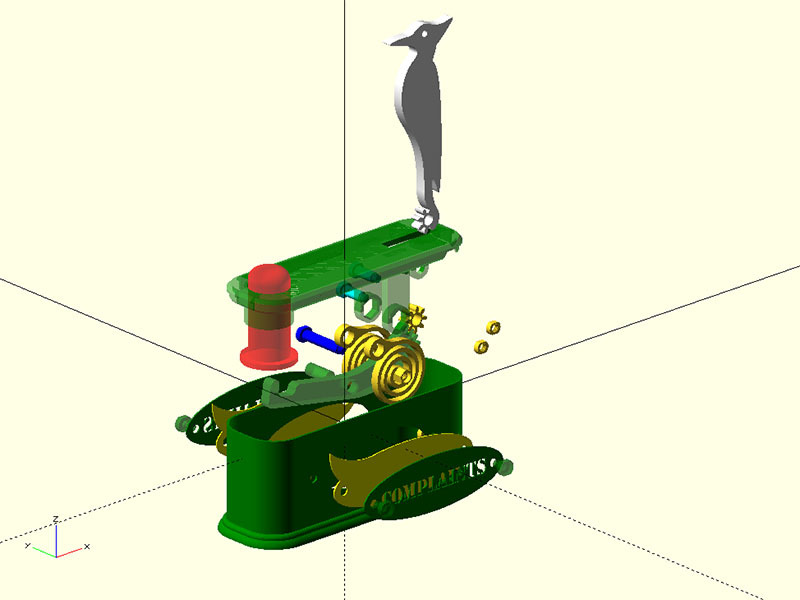

Remix of Complaint Button

thingiverse

I really loved this design, but the tolerances were a bit too tight for my printer. I decided to redo the axles & pins, and then got carried away and changed everything except the button. I converted the 8mm axles into an 8mm bolt with 6mm threads on the end. By doing this, I had to cut an access slot for the hole where the woodpecker gear connects. This is not noticeable when the top is attached to the bottom. Since I had to change the top, I also decided to round the corners as well & they are customizable in the openscad script. I used a radius of 20mm for the corners, but up to 28mm should work. Don't use less than 2mm for the radius as I didn't allow for sharp corners in the code. I generally had a tolerance of .4mm for axles, holes & threaded parts. The threaded parts I used a non-standard threading for better printing at .2mm layer height, by changing the thread pitch from 1.0 to 1.25 & Thread_Angle = 40. To modify any of the openscad files that use the threading, you will need to download the **threads.scad** file from http://dkprojects.net/openscad-threads/. There are 2 versions of the base, one with cutouts for the sign(**Base_Mod_WithCutouts_Rev5.stl**) I am using & one without cutouts(**Base_Mod_Rev5.stl**). You should be able to print 1 each of the parts, except print 2 each of the **Complaints_Blank.stl** & **Complaints_Text.stl**. The **AxleShort_WithNut_Rev5.stl** are 2 axles with nuts to connect to the woodpecker gear & small gear. The **AxleLong_WithNut_Rev7.stl** goes in middle of the springs. I print 2 of these for longer printing per layer, but you only need 1 of these. The **PinLong_WithNut_Rev7.stl** goes at the end of the spring connection. The **ComplaintScrews_WithNuts_Rev3.stl** are the screws & nuts to connect the Complaint Text. Follow the directions from the original design: https://www.thingiverse.com/thing:2882432 for installing this. The STL files I generated worked for me with any sanding, but think I do need to sand the top and bottom of the woodpecker gear for smoother movement. I used .2mm layer height for all prints except for the Top & Base I used variable layer height with the Slic3r Prusa Edition 1.40.0-beta. This saves probably 30 minutes on each of those prints. For the top I used these layer ranges //Top Variable Slicing Layers //0 - 2.35 .2 //2.35 - 6.75 .3 //6.75 - 26.15 .2 //26.15 - 40.95 .3 //40.95 - 58.35 .2 If you use the base without the cutouts, you could use .3mm for all the layers //Base Variable layer slicing //0 - 24.75 .3 //24.75 - 62.55 .2 //62.55 - 77.95 .3 The openscad file for the Spring_Left_Mod_Rev2.scad is also used to generate the Right spring. It is just mirrored about one of the axis. I would like to change the text a little better, but that works for now. If I missed something let me know.

With this file you will be able to print Remix of Complaint Button with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Remix of Complaint Button.