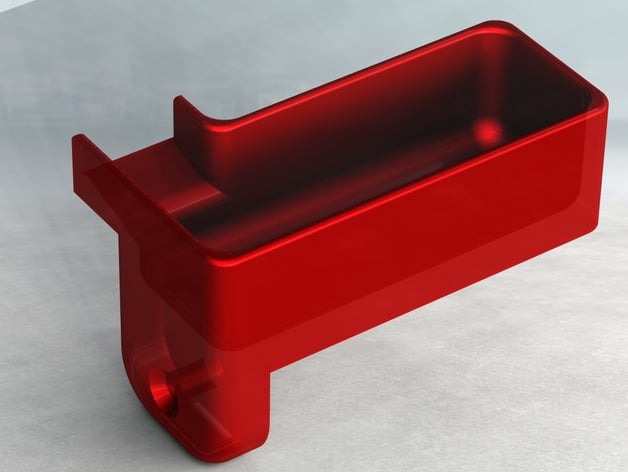

RCBS Primer Catcher Catcher

thingiverse

TL;DR: for when you don't have a suitable/design-intended hose on hand to send your spent primers into the garbage. It uses a 'negligible' amount of filament instead. I love the new primer catcher my RCBS Rock Chucker sports:http://www.thingiverse.com/thing:1223108 Might also work with this primer catcher:http://www.thingiverse.com/thing:148190, Or its predecessor:http://www.thingiverse.com/thing:84047. While it works well (much better than stock piece of sh!t), the spent primers are dumped onto the floor unless connected to a trash can with a 1/2" vinyl hose. I just taped a bag onto the spout, but it fell off after a bit. Anyway, I don't have a hose, but I do have a 3D printer, so I made this Thing to catch the primers from the primer catcher, hence primer catcher catcher. There is also an optional countersunk #8 screw hole to keep it in place. Inside edges are blended to make removal of spent primers with fingers easier, should you choose to secure it, and to help with printing in recommended orientation. There is a 75 mm version and a 100 mm version, that runs the entire length of the Rock Chucker. I did the 75 first to test fit, and it works well enough for me. If you're screwing it down it might make more sense to use the 100 mm version to hold more spent primers in between emptying. The model is fully parametric, so any length could be made if you can open the .prt file and edit the dimensions. (sorry no OpenSCAD) Works best on a slightly angled surface, like this portable reloading bench I made:http://precisionrifleblog.com/2012/11/12/portable-reloading-press-plans/ All credit for that goes to "Cal" from precisionrifleblog.com for the design of that stand. Pictures included in case you want to make your own! Only took me 4 hours or so, going slow and trying to be as precise as possible. But I did have the right tools for the job, so YMMV Printer: FFCreat0r Rafts: Yes Supports: No Resolution: 200 micron Infill: 10% Notes: Print Catcher100V1.1.stl (the bigger one) Recommended print orientation shown in Makerware picture. I use raft since I printed in ABS, but whatever works. PLA shouldn't need one. No supports, since edge blends should get the ends close enough to bridge as it reaches the top layers. File it down to fit if needed. 0.2mm, 2 shells, 10% infill Post-Printing Use #8 screw to secure to your reloading bench if desired Resulting droop from no supports. Just scrape off with a knife How I Designed This 100 Large Rifle Primers 250 Large Rifle Primers (still room for more so I guess I was off with the capacity) Took some very crude measurements with a caliper, modeled it up without a preliminary sketch, and printed. Works great and only took 30-60 min to design. The fifth picture shows the Primer Catcher Catcher after decapping 100 cases. I'm estimating that it could hold 100 more (the 75 mm version, large rifle primers). Doing some math: X, Y and Z thickness = 2 mm 75 mm vol: (75-22mm)(30-22mm)(24-2mm) = 40,612 mm^3 100: (100-22mm)(30-22mm)(24-2mm) = 54,912 mm^3 Dividing yields 1.3521, so the 100 mm one has about 35% more volume, which should equate to 270-300 primers. So you can get an extra 100 primers into the bigger one. Just print that unless you're out of filament, I only made the smaller one because I didn't know if my crude measurements were refined enough.

With this file you will be able to print RCBS Primer Catcher Catcher with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RCBS Primer Catcher Catcher.