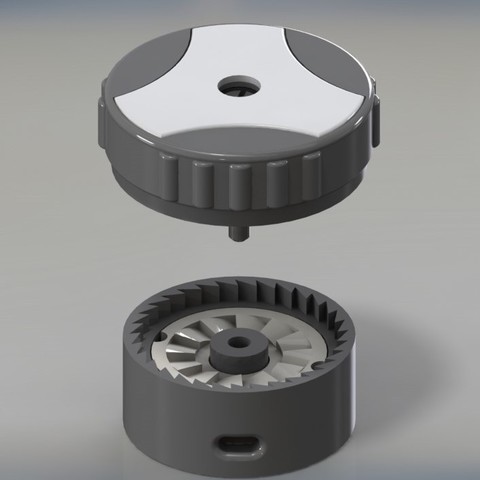

RATCHET CLAMPING SYSTEM

thingiverse

I am currently working on a prosthesis project that would enable children with agenesis to ski. To ensure the ski pole is securely attached to the prosthesis, I designed a wheel clamping system. This system consists of a mechanical component with low tolerances. I recommend printing all parts with a layer height of 0.1mm for optimal results. The principle of this device is simple: turning the knob clockwise winds the cord, while the pawls prevent it from unwinding. To loosen the cord, simply pull the knob and the coil will be released. You can adapt this device to your specific needs. It's a first draft that's being improved but works very well so far. I used PLA and a 0.4mm nozzle for printing. The ratchet part comes with an STL file featuring a support offset of 0.3mm, making it easier to print without additional support. The circular spring inside the knob and the pattern on top must be glued together. The pawl is inserted into the circular spring using three tabs, while the spacer must be placed between the ratchet disc and the circular spring. The corp_2 part serves as a fixing point with M3 screws, and corp_3 is used for sewing fixation. Use a 20mm M3 screw and an M3 hexagonal nut to secure everything in place. For the cord, please follow the attached pictures. Before final assembly, verify that the spacer slides smoothly on both the spring and ratchet disc. This device was originally designed for a project involving electronically assisted hands, as shown at this link: https://www.gre-nable.fr/en/electrically-assisted-flexibone-hand/.

With this file you will be able to print RATCHET CLAMPING SYSTEM with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on RATCHET CLAMPING SYSTEM.