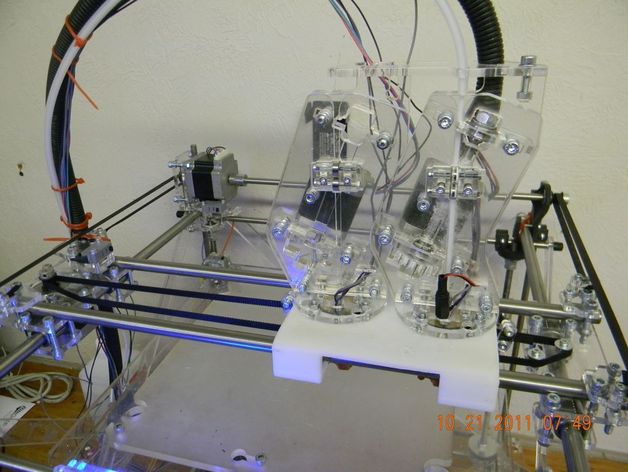

Rapman Dual Extruder Plate

thingiverse

The one-piece dual extruder plate includes linear bearing housings, reducing the need for a spacer plate between the extruder carriage and extruder. Redesigned for PLA and ABS printability, it offers smooth cylindrical prints with minimal Z-axis wobble. The plate can be easily installed on the print bed in Axon, with instructions provided for optimal placement using examples (Figures 1 & 2). Axon settings for PLA are given, but adjustments may be necessary based on individual printer specifications. Printing time is approximately 7 hours, followed by a raft removal and cleaning process. To assemble the extruder carriage, insert linear bearings tightly (do not drill unless necessary) and secure nuts and screws for mounting the extruder to the carriage. Use pliers for proper nut placement, ensuring a firm and solid mount. Reassemble the X-axis rods and retainers on the Y-axis carrier and attach the extruders as per original instructions. The X-Axis stop switch may require adjustment due to the thicker carriage; add 5-7 thin washers if necessary for proper alignment. Finally, align print nozzles and set Z-height before continuing with regular printing operations on an improved extruder carriage without worrying about falling screws.

With this file you will be able to print Rapman Dual Extruder Plate with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Rapman Dual Extruder Plate.