Raiscube A8R X upgrades

thingiverse

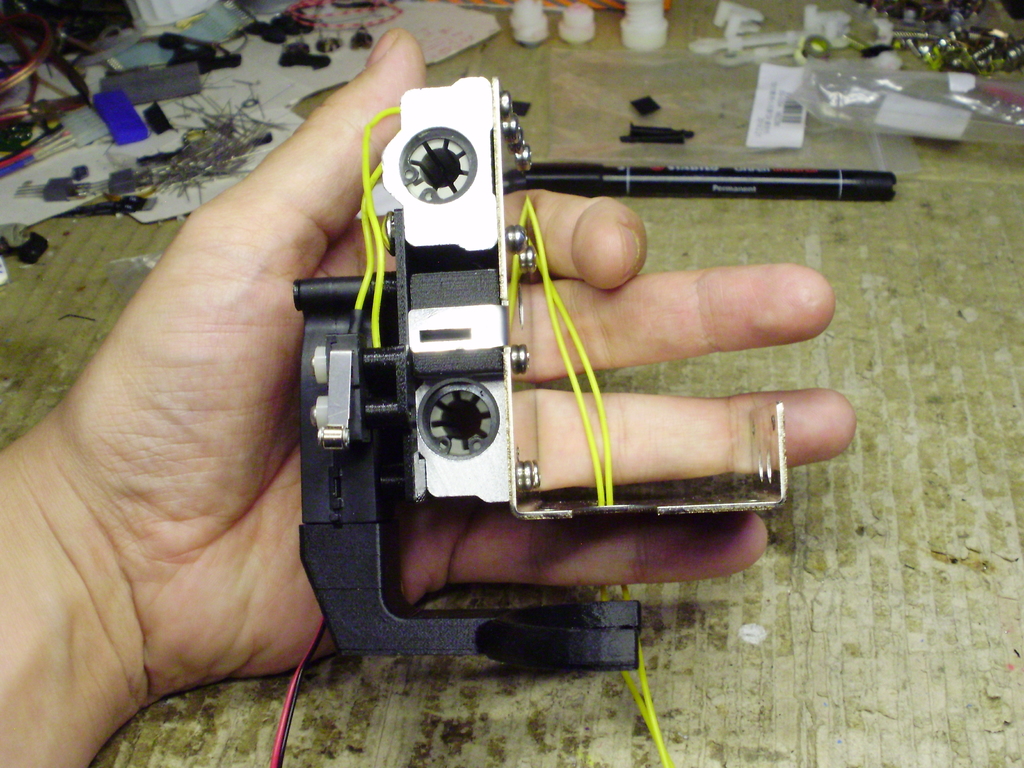

This is an upgrade of the X belt clamp / cooling system for Raiscube A8R 3D printer. This unit comes with a highly cumbersome extruder assembly, sporting an inefficient but impressively large cooling system. It utilizes two massive 40mm axial fans, each with a substantial air duct and a very narrow exhaust nozzle, resulting in woefully inadequate airflow. I had to do something about it. At the same time, I wanted to make the traditional cable-tie type "belt clamp" better. Here I was hesitating for a while, weighing my options for the variable clamp (tightening side). I initially thought about using a screw, but then saw a solution developed for Anet A8 printers that used a rotating ratchet wheel and really liked it. Unfortunately, here I had no space to implement this, so at the end I came up with a simple curved belt duct and a small wedge. One can pull the belt tight by hand, and then push the little wedge in to lock it. Belt tension tries to pull the wedge even more in, causing it to self-lock. Regarding the fan: I wanted full visibility to the nozzle, so thought to use a semi-circular air duct, placing the fan at the back. To secure the fan, I designed a small bracket that simultaneously holds the X home switch as well. The air duct is a remix of thing#2322182 , modified to have a necessary recess to push it into the fan's output port, and was mirrored and lengthened to arrive at the correct spot. As an extra: I planned to fix the fan to the bracket using M3x20 screws, but found out that I didn't have them at home. So, as I have a hammer, everything looks like a nail, doesn't it? I modeled and printed even the two pins used to secure the fan in place. The last photo is a before/after: the black pin was printed with the original cooling system, the blue one with the modified. Same gcode file, nothing modified or tweaked yet! UPDATE 02/09/2019: During the past months of using the printer, I discovered a design flaw. It appears that the weight of the air duct is pulling down the whole assembly and by the axis of the two pins, it manages to actually tilt downwards and the end of the duct starts to touch or even crash into the item under print (on one occasion this was so violent it actually kicked off the item from the build plate...) To solve the issue I designed a small clamp that connects the lower part of the fan to the mount plate. The item must be printed lying on its side as this way it is much stronger and can withstand the pulling forces. The other modification is a small mount for the cooling fan: originally it was mounted directly on the side of the extruder aluminium block. This actually blocks the air flow completely, so there's no cooling effect at all. By moving the fan a little more downwards and further away, there will be some airflow, which in turn can provide some cooling effect. I've replaced the original metal fan grill with this reduced frame aperture design by mightynozzle as I really like it.

With this file you will be able to print Raiscube A8R X upgrades with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Raiscube A8R X upgrades.