Radio control jetboat

pinshape

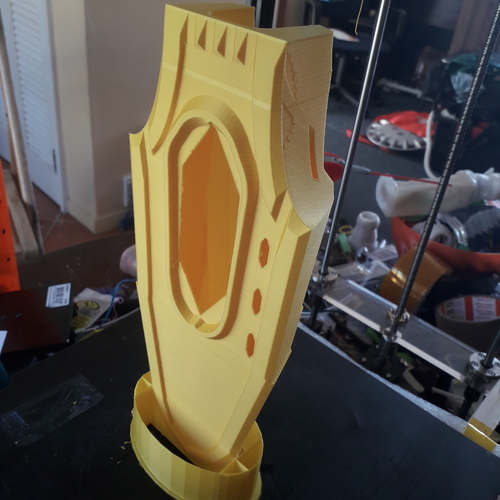

You need a large delta or cube to print this design scale, XL to print it design size. There are several cool features: 1. All riding surfaces are flat to avoid the clinginess of the Coandä effect present with regular boats. 2. There is some concave curvature in stern side cutouts, this reduces stern lift and prevents bow-diving during on-edge operation. 3. I've revised all the steps to provide small internal bridging support fillets, requiring a bridging fan for tidiest printing. I recommend 0.1mm layers and 10 top layers. 4. The deck prints with the boat including a hatch moulding and cutout. 5. There are side buoyancy chambers. The boat is intended for printing with bow down to the build plate, I've added a custom support structure. During printing, add some PVA glue where you see small gaps to the support structure, this will hold during printing and break away perfectly after printing. When slicing, review all layers before starting the print if you scale or print with an unusually large nozzle. Ensure your nozzle build width is set correctly, as non-waterproof prints indicate a wrong nozzle setting. Many slicers have advanced settings that relate to layer height, not nozzle orifice width. Use a peremiter size of at least the actual nozzle orifice size for solid perimeter and interlayer bonding. For full-sized printing, this boat suits a 35mm jet unit and a water-cooled 36mm diameter inrunner motor. I've attached details of what I used from hobby king. 1/2 size: THE TORTURE TEST Initial photos are with a self-righting flood chamber. However, the boat is too beamy, so I've converted to all sealed chambers and a centre chamber with the hatch. The inside of the transom where the jet intake fits requires good bridging, but it prints fine on my machine even with a poor bridging fan. I recommend setting 0.45mm extrusion width for 1/2 scale printing if using a 0.4mm nozzle, this gives minimum double wall thickness which should be waterproof if your filament diameter, extruder motor calibration and extrude drive dog are all working reliably. Be careful going too thick when printing at half scale as several layers are needed to correctly form the hull steps tidily. For half-scale I'd recommend a 3000kV x 24mm x 37mm long or similar inrunner for 3S and 4500kV for 2S. Outrunners have a bigger torque effect spinning up to speed, enough that you are likely to flip the boat around its long axis any time the boat is airborne as the unloaded motor accelerates. Placing the batteries wide fights this but inrunners are recommended. Quick note on pricing... this is just a little incentive to keep me productive ;-) The cost of filament for a 1/2 scale print is actually more than the price for the model download! Favorite the design and check back for updates, I may do a variant with inbuilt intake and [stator, steering nozzle accessories].

With this file you will be able to print Radio control jetboat with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Radio control jetboat.