Quick-disassembly for buda hot end/extruder/x-carriage

thingiverse

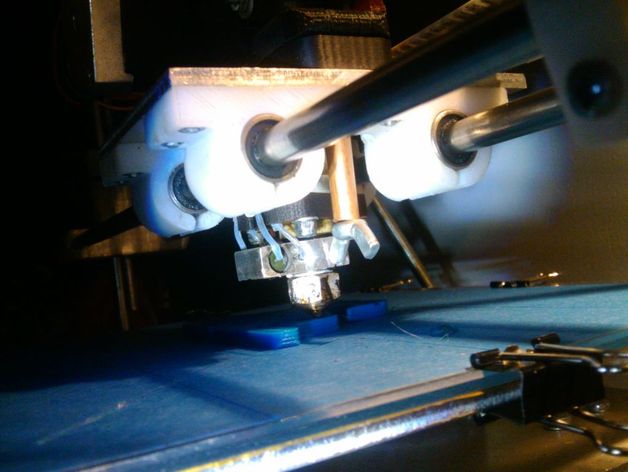

Effortlessly disassemble Buda hot ends with connected extruders, particularly those featuring sunken-in hex head depressions. To simplify the process, upgrade your old Prusa extruder to a newer one like Greg's accessible extruder and an Airwolf hot end. To enhance this setup, use two of the four M4 bolts from the previous extruder idler to hold the new extruder to both the hot end and x-carriage, along with two M4 wingnuts from the old assembly. Cut a small copper pipe piece for the wingnuts' placement adjustment. This quick-disconnect assembly allows for rapid dismantling of the entire x-carriage without tools, ideal for fixing jams or cleaning hot ends. Suitable for various machines, including Longboat Prusa. Additionally, an STL file is provided for a spacer that complements new extruders by filling the bottom space effectively.

With this file you will be able to print Quick-disassembly for buda hot end/extruder/x-carriage with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Quick-disassembly for buda hot end/extruder/x-carriage.