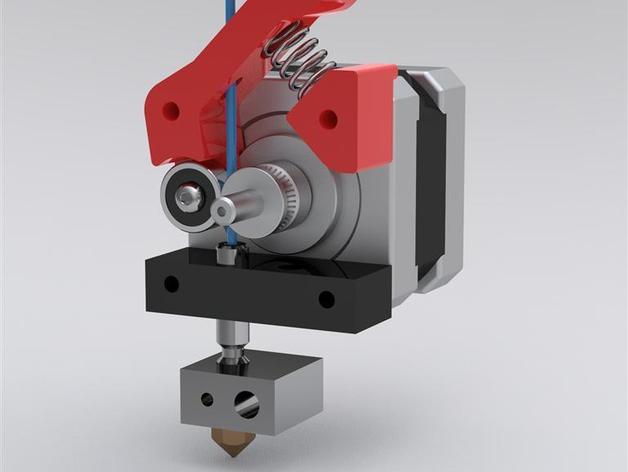

QU-BD Extruder Modifications

thingiverse

To fix a frequently stopping QU-BD extruder, switch to a spring-loaded idler pulley. This modification works with the stock QU-BD drive gear but is enhanced by using an MK7 style drive gear. Two versions of parts are available for running filament through either the right or left side. You'll need a 4mm I.D. x 13mm O.D x 5mm thk bearing (624), a button head 4mm x 10 screw, a 4mm washer, and a spring. A 3/8" x 1-1/8" x 0.047 spring from a Home Depot assortment pack can be used. The assembly fits within the width of the motor, allowing for two side by side. For more details and a wiki page on QU-BD extruder improvements, visit http://www.buildlog.net/wiki/doku.php?id=ord_bot:qu-bd_extruder_improvements. For assembly, choose the appropriate version based on filament side placement and print the parts. Clean out the holes with a 3mm drill. Assemble the lever, bearing, washer, and screw, self-tapping the screw into the lever. Attach all components to the extruder except the lever, ensuring the spring block's bump points towards the motor for stability. Install the lever with the spring while compressing it, and secure with a screw without over-tightening. The inspiration came from this thing: http://www.thingiverse.com/thing:15718

With this file you will be able to print QU-BD Extruder Modifications with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on QU-BD Extruder Modifications.