Pulley design

myminifactory

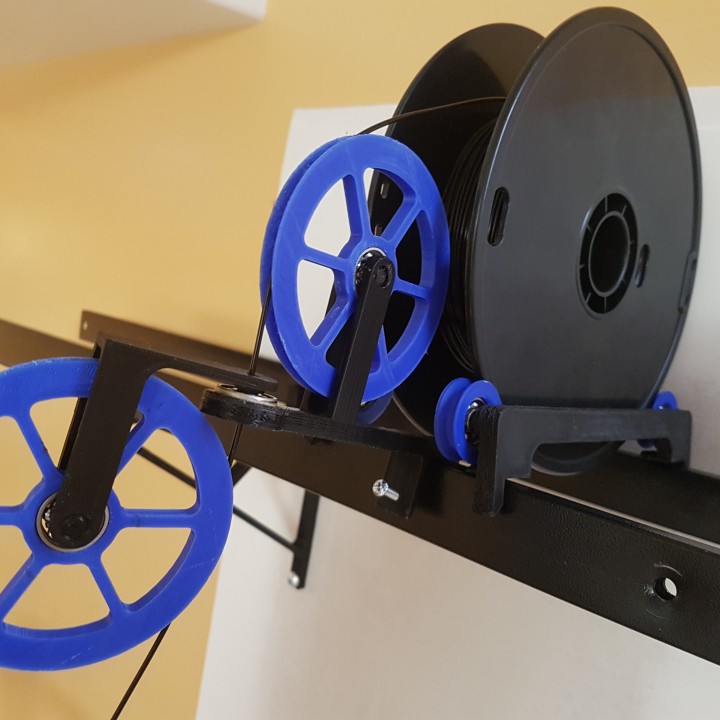

As discussed in my previous design "Funnel on pipe design", the existing brackets appear sound in terms of stress, but there are potential risks of failure over time due to wear and tear, shock loading or fatigue. However, if you still wish to proceed with the existing bracket, I suggest adding new brackets between the existing ones. Furthermore, I do not recommend mounting a spool holder at the edge of the brackets as this will result in excessive overhang, leading to a greater amount of torque that could cause the brackets to break or become detached. This revised design necessitates 9 bearings, which I obtained from a figit spinner, featuring an ID of 0.25 inches, an OD of 0.75 inches and a width of 0.25 inches. Four bearings will be used for spool mounting, three for the pulley system near the spool, and two at the machine. Please note that you may need to multiply these quantities according to your specific requirements. A screw with dimensions 6-32 x 1/2 inch in length is required for mounting the pulley system on my machine. The lengths of other screws will vary depending on their intended use. To ensure the longevity and durability of all parts, I strongly recommend printing them using ABS or a stronger material with 100% fill density. For assembly purposes, I have attached both the 3D PDF and CAD file for your reference.

With this file you will be able to print Pulley design with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pulley design.