Prusa PCB Factory : Draw and Drill pcbs

thingiverse

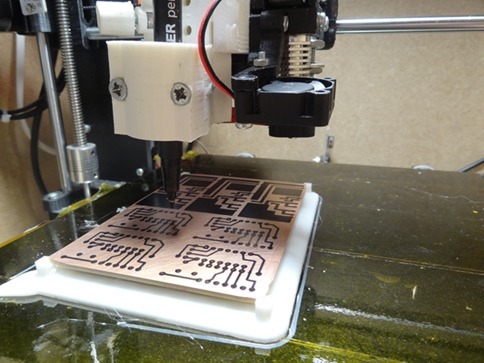

How to use your 3D printer to create PCBs ? This is an experiment to demonstrate how a 3D printer can be used for drawing and drilling PCBs. I have designed a tool holder that allows adding tools to the printer head without compromising its 3D printing capabilities. The principle behind this design is simple: add the tool when needed, remove it when not in use, allowing you to switch between 3D printing and PCB creation seamlessly. A small utility software is required to convert circuit designs into gcode files. I use Design Spark 7.2 to design my PCBs, then a utility script that converts the files into gcode information. The objective is to be able to draw with an etch resist pen and drill on copper clads, with etching still necessary. The key principle of this experiment is that the utility software reads the PCB design and generates a gcode file to print a plastic support at a precise position on your printer bed, with exact dimensions matching your desired PCB. The generated gcode files use 1.75mm PLA filament, requiring an ini file modification for different printer settings. To set this up, you'll need to leave the printed plastic support in place and reinforce it using scotch tape to prevent movement during the process. Once secure, place your copper clad on top and launch the gcode files to draw and drill at precise positions. Here are four key points to replicate this experiment: A. Find a way to fix the tool holder securely without removing the PLA head from your printer. I've provided STL files for holding the pen and drill, but you can use any solution as long as it meets these requirements: 1) The gohome (x=0,y=0,z=0) command must work with tools mounted. 2) The tool holder should not replace the printer's PLA head. 3) I've only tested this on a Prusa i3, so design adjustments may be necessary for other printers. 4) Tool holders are modular; you'll need to screw together a tool slider and holder of the correct diameter, then slide it into the MultitoolRail. B. Calibrate your tools: move the edge of each tool (pen or drill) to the edge of the arrow on the plastic support and read x,y,z values from your printer. Update the ini file with this information and generate all gcode files to draw and drill, knowing exactly how to move the tools on the plastic support. C. Print and drill the PCB: once you've prepared calibration and generated gcode files, place your copper clad on top of the printed plastic support. This ensures precise positioning on your printer bed. Run the pen_copper_top.gcode to draw the PCB tracks using an etch resist pen; then launch the gcode file for drilling (one per drill size). Don't forget to etch the PCB. D. Software: you'll need to install additional free software, including slic3r.exe and openscad.exe, as well as DesignSpark 7.2 PCB editing software to export odb++ files. More detailed instructions and downloads are available at http://prusapcbfactory.highlevelbits.fr/index.php. You can test this concept with a test circuit board: https://www.thingiverse.com/thing:2469533, which hosts an MCP3008 volt Analog converter (SPI).

With this file you will be able to print Prusa PCB Factory : Draw and Drill pcbs with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa PCB Factory : Draw and Drill pcbs.