Prusa Mendel Caliper Clamps for Calibration

thingiverse

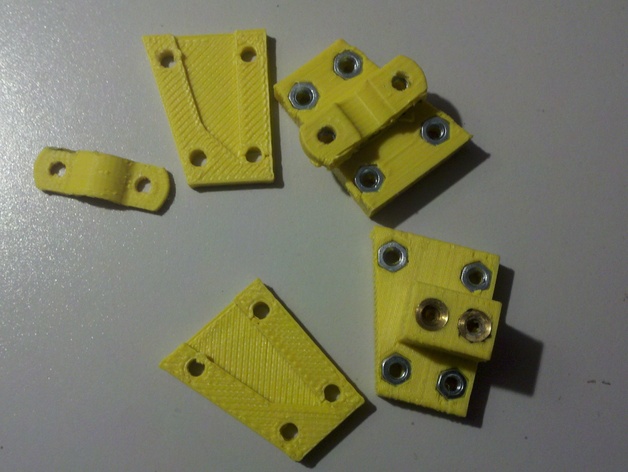

Inspired by "thecrazy's" fantastic work, I created personalized caliper clamps to enhance my Mendel accuracy. Despite some imperfect parts, photos reflect the instructions below. Requirements include 10 M3 nuts, 2 M3 3.8mm heatset inserts or nuts for filament holder, and 8 M3 x 15mm screws. Optional are 10 M3 washers. To assemble: print bar clamp, back half, filament holder, and two front halves; insert nuts/heatset inserts with a soldering iron; join front and back halves around calipers using screws; attach clamp to the Y-axis frame member. Next, home the Y-axis, zero calipers, jog 100mm, repeat, average results, adjust firmware if necessary. For X-Axis, attach clamp to Z-axis smooth rod, home and extend calipers, zero, jog 100mm, repeat. Finally, for Z-Axis, attach above extruder, measure like Y and X, add filament holder and front halves, align X-Axis for straight filament feed, feed through holder into extruder, clamp using set screws, extrude 1-2mm to remove slack, zero calipers, and extrude in 10mm increments. Repeat process until precision exceeds caliper capabilities.

With this file you will be able to print Prusa Mendel Caliper Clamps for Calibration with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa Mendel Caliper Clamps for Calibration.