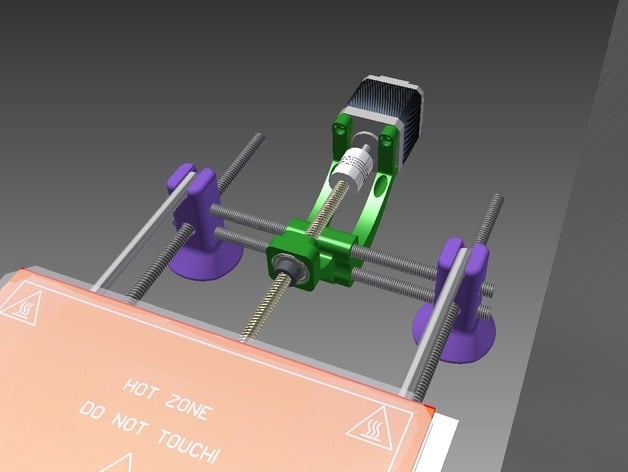

Prusa i3 Y-axis lead screw upgrade

thingiverse

We'd decided to go with the lead screw instead of belt drive due to inconsistency issues and backlash we encountered with our initial design. Our initial trials were focused on the Y-axis, and so far, it's been going well. UPDATE: Our X-Axis lead screw upgrade is now available here for matching! Alongside our motor and bearing mounts, we also revamped the bead by modifying the frame foot design. It's essential to note that this new setup will only be functional if you utilize the taller frame feet provided; they're designed specifically around an 8mm rod frame build. Source files can now be found in Thing Files. Here are some key notes: Bearing mounts require printing with supports and are easy to clean up afterwards. The base is printed in PLA, while lead-screw components were printed in ABS. A huge thanks goes out to ePoxi for the incredible Mechanical Y-EndStop holder designed specifically for Prusa i3 found here. Excellent work! Updates include: Jan 12th, 2015: Uploaded improved plate-follower coupler bracket STL with added ribs for enhanced rigidity. Jan 12th, 2015: Uploaded bed cable guide STL as an option, which can be easily mounted onto the Nema 17 using zip ties to prevent the cable bundle from snagging. We've also got some fantastic mods available: Jan 18th, 2015: ePoxi.i3.Y-Endstop.BetterHalfMod.STL that we're currently utilizing. A solid end-stop design highly recommended. Jan 21st: Added a YouTube video of us printing a test object for a closer look. For an in-depth view of our finished prints (untouched), you can check out the imgur album. The test print was the Deprime test object, which can be found here on thingiverse. Our setup is using Repetier Host V1.0.6 and Slic3r V1.1.7 for smooth printing. We're currently running the following settings: Layer Height: .15mm Print Speed: 30% of the first layer, with an additional 60mm/sec for infill To view a more in-depth print setup guide and part list, check out our Instructions tab for crucial information on assembly. For those interested, here are some necessary parts sourced from openbuildspartstore.com: * Lead screw: cut into half, with the other half being used for the X-axis * Nut Plate * Lock Collars 8mm I.D. x2 * Coupler Fits Nema shaft and 8mm lead screw Additionally required components include: M3 x 20mm (ish) bolts (x2) M4 washer (x2) And of course, the new parts will be sourced from our supplier for smooth integration with the original Prusa frame. Notes on printing: The bearing mounts should be printed with supports and are easy to generate. Be aware that the lead-screw follower may be a bit stubborn initially due to the stiff nut plate. Before attempting any prints, use lubrication and turn the axis by hand several times from home to full range. Important adjustments: * For better resolution in our 1/16th microstep mode (steps/mm approximately), try increasing your Y-axis steps to about 400 per millimeter. However, reducing to 1/4 microsteps might be more beneficial as it increases torque from the stepper motor. If stalling occurs while moving at high speed, lower max travel and acceleration accordingly. It's also suggested to add some sort of grip to Prusa feet, which can easily be accomplished with either cutting out rubber circles or printing NinjaFlex discs.

With this file you will be able to print Prusa i3 Y-axis lead screw upgrade with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa i3 Y-axis lead screw upgrade.