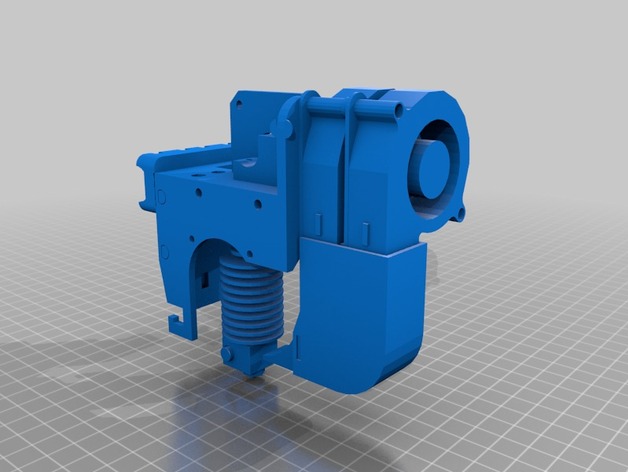

Prusa i3 e3d+MK8

thingiverse

The 3D printer, specifically a model that incorporates an E3D MK8 hotend, offers great potential for producing complex and detailed designs quickly. The ability to switch between two hotends, the MK7 or MK8, adds flexibility when using this specific Prusa I3 machine with dual extrusion capability is quite impressive. However, precise tuning of extrusion rates is essential to maintain even layers on models with varying shapes. A major factor that affects the outcome is the heat sink size: the smaller variant works best for large parts while larger items perform better with the extra-large variant installed. When operating with either nozzle size variation as described here in conjunction with Prusa's e3d mk8 equipped print, certain printing issues arise if proper calibration isn't executed prior to actual usage. First off you need make sure correct settings of extrusion rate speed (both high and low range are provided through printer menus ) as this variable has substantial impact overall success during a session running like any complex build projects like these with precision. These results prove it; one may conclude it requires good control management via software - particularly firmware options specifically suited towards dual print heads which significantly impacts desired result for large object models in relation quality achieved at time printing began and end results show consistency across printed layers due careful initial settings followed post operation monitoring to finalize optimal values leading successful project completion under test conditions performed above mentioned hardware setup utilizing its designed intent capabilities fully leveraged within software configurations. A good Prusa I3 print, particularly with the e3d mk8 set-up attached works as an incredibly fast tool but it can create inconsistent and imperfect layers on larger items due mainly extruder settings - these adjustments could require more frequent calibrations. To resolve this one must first change your speed setting which also will depend how much filament goes in (so faster prints don't clog or make errors during print.) In practice using a large heatsink does significantly better results so they generally recommended when you start creating bigger prints that require good detail. But I want to share that dual head 3D printer setup and its performance is an interesting area. With all these specifics let me conclude: Prusa's i3 plus MK8 set-up, used by hobbyist or professional can easily yield quality output but must have fine-grained settings and adjustments in order achieve successful end product due specific operational parameters.

With this file you will be able to print Prusa i3 e3d+MK8 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa i3 e3d+MK8.