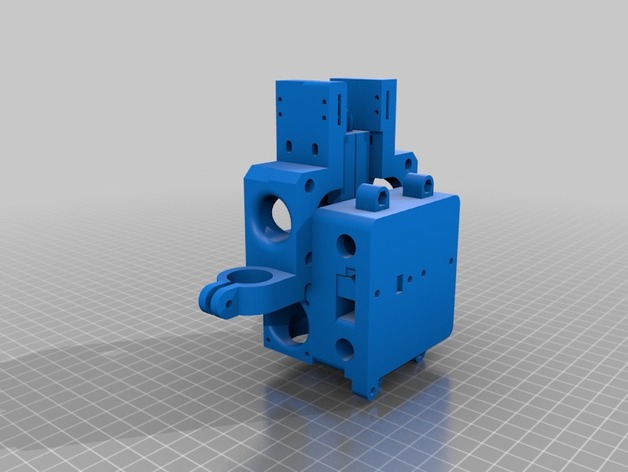

Prusa i3 Dual Extruder Design

thingiverse

This is my take on a dual extruder setup for Prusa i3 machines. It uses two genuine E3D-V6 extruders, supporting British innovation, so be sure to check sizes if clones are used. The setup can be assembled as a side-by-side or front-and-rear layout and includes an optional 18mm Diameter capacitive Z-Probe mount and Filament Runout switch mount. It also has the option of either three or four linear bearings, with one extruder being adjustable in both cases. Different arrangements have their pros and cons. The Front/Rear setup has the advantage of a more balanced design but has the disadvantage of reducing the Z axis to about 160mm and the Y axis to about 180mm. On the other hand, the Side by Side layout is front-heavy but allows full X, Y, and Z movement. Three bearings may have lower friction than four bearings but may wear faster and possibly not be as accurate. I've tried the three-bearing setup first and will report back on its performance later. Depending on your required arrangement, you'll need to mirror some extruder body parts. For example, for a side-by-side design with no Z-Probe or RunOut switch, you'll need two Extruder Body Basics and two Extruder Body Basics mirrored (flipped about Y if using Slic3r). The Extruder body that's adjustable needs the Adjuster Lug glued into it (if printed in ABS, then a dab of acetone is perfect) so that it locates in the X-Carriage Front. A 3mm cap head screw is screwed into the lug and locates into the carriage. The extruder body is fixed to the carried by 3mm cap head screws in two slotted holes, tighten the screws a little then use an allen key to make the Z adjustment. A fan can be mounted on the rear X-Carriage if required; glue the Fan Lug in place. The fan mount and duct are the ones supplied with the Prusa i3 Plus Original from Prusa Research as they're Open Source. I've included the STL file for this as well. A suitable fan is available at http://www.ebay.co.uk/itm/161834906059?_trksid=p2055119.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT. The Capacitive probe I used is one of these: http://www.ebay.co.uk/itm/291369250165?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT. If you need a 12mm diameter probe, either make an adaptor or let me know and I'll modify the part for you. The Filament RunOut Sensor is a simple micro-switch with a lever and roller: http://www.ebay.co.uk/itm/281854711611?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT. The Extruder fans should be assembled so that both blow in the same direction to get a through flow of cooling air. If going for the Front/Rear layout, you have three Carriage options including a slightly narrower 3-bearing design. Printer Settings: Printer Brand: RepRap Printer: Prusa i3 Plus Rafts: No Supports: Yes Resolution: 200 micron Infill: 25% Notes: Print in either ABS or PET if you want it a bit less brittle. Supports are only needed for the lugs that hold the X-Carriage together. How I Designed This: Designed in AutoCAD 2016 on a Mac, possibly not the best choice but I've been using AutoCAD now for 30+ years!!! If anyone wants the files, let me know.

With this file you will be able to print Prusa i3 Dual Extruder Design with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Prusa i3 Dual Extruder Design.