Proxxon MF70 43mm Mill Print Upgrade

thingiverse

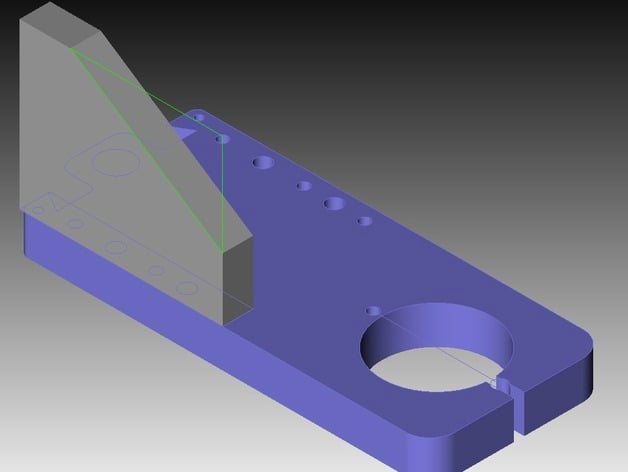

The desired setup includes a 3-axis mill with a 60° milling head for working with aluminum and printed circuit boards (PCBs). Additionally, a 3D printer is incorporated. The spindle is a standard ball bearing type with an M14 nut driven by the Z axis of the mill. The control system is based on RAMPS 1.4 with stepper motors and endstops. To implement this solution, follow these steps: 1) Mill the baseplate using CUT2d or Deskproto; 2) Mill the side plate, with an update planned to mount the print head 180° turned for better weight distribution; 3) Drill holes in the sidewalls as required; 4) drill H7 holes of 6mm diameter; 5) assemble all components to mill the 60° side guards, using an existing Z guard for a proper fit (this step may need to be done twice); 6) mount the steppers and test the machine; 7) configure Marlin firmware to allow dangerous prints; and finally, enjoy your combined milling and printing capabilities.

With this file you will be able to print Proxxon MF70 43mm Mill Print Upgrade with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Proxxon MF70 43mm Mill Print Upgrade.