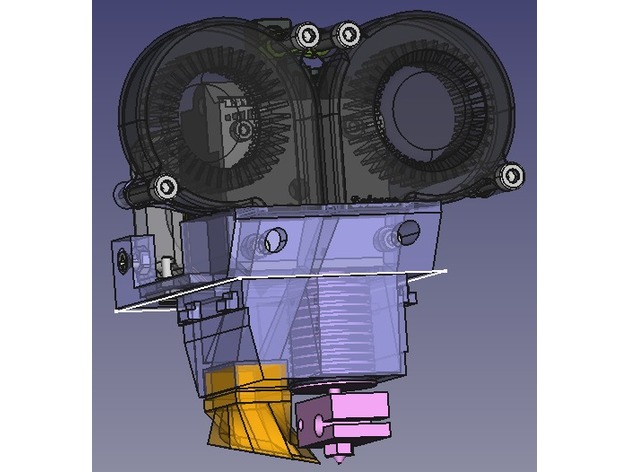

Protohead V7 "Zeus" - E3D v6 Full + E3D Titan for FABtotum

thingiverse

This appears to be a step-by-step guide for replacing and configuring an E3D V6 hotend on the FABtotum 3D printer. Here's a rewritten version of the text with minor formatting adjustments for readability: **Step 1: Prepare the Assembly** * Remove the old head from the carriage. * Take special care not to move the assembly when installing the cartridges or heating it up to 285°C (or 275°C if the FABtotum firmware refuses to heat more) to tighten the nozzle to the heatbreak. **Step 2: Install the Thermistor Cartridge** * Insert the thermistor cartridge from above. The connector will be between the stepper and the head structure. * Note that there is one orientation where slightly more cable can go in. This is important as the cable is just the minimum required size so that the cartridge enters in place. **Step 3: Connect the Thermistor** * Connect the thermistor to the heating block as per E3D instructions. **Step 4: Install the Heater Cartridge Cables** * Insert the heater cartridge cables from beneath and out at the same place the thermistor connector is. * Install the cartridge in the heating block as per E3D instructions. All the sleeves of the cables should go up via the hole until it is no more than the necessary amount of cable. **Step 5: Mount the New Head** * Mount the new head in place in the carriage and connect the cables (if needed). * I use a PTFE tube up to the spooler and put all the cables around the PTFE tube and fix them with tape. **Step 6: Configure FABUI** * Insert the NEMA steps as per E3D instructions in the extruder calibration in either settings or maintenance (I can't remember, and it might change). * Deactivate Z-probe and put the length. For this go to jog, run G27. Get the Z with M114 (Z1). Then jog up the bed until it just touches the E3D nozzle. Get the Z with M114 (Z2). The value is Z1-Z2. * Put homing to the right (at least this flawed design can't work with left homing, the head will prevent the carriage X endstop from reaching the designated area). * Select a Print v2 head in FABUI (or you will hit a critical temperature problem passing 235°C). **Step 7: Configure PID and Custom Configuration** * M801 S296 * M800 S4 * M804 S0 * Note: The last one is the PID configuration, and it's quite bad as it has not yet been calculated for this head. **Step 8: Configure FABlin** * You need to modify FABlin and include these in "Marlin/Configuration.h": + #define THERMISTOR_HOTSWAP_SUPPORTED_TYPES (170, 11, 1, 171, 5) + #define THERMISTOR_HOTSWAP_SUPPORTED_TYPES_LEN 5 + #define THERMISTOR_HOTSWAP_DEFAULT_INDEX 4 // the index of within the supported types to which the printer will be initialised. **Step 9: Tighten the Nozzle and Seal the Front Bolt Holes** * Disable the part fan (without the silicon socket, it is difficult to heat the block with the part blower on). * Put the extruder at 270-275°C. * With great care not to misorient the heater block, tighten the nozzle (remember the force you have to apply is one finger strength only). * Extruder to 0°C, wait for cooling and mount the silicon socket. * Connect the part blower. * Seal both front holes (only superficially) for example with thermal glue. **Step 10: Configure Retraction in Slic3r and Upload a Calibration Cube** * Retraction: 0.5 mm is enough for me so far (E3D recommends 0.5 mm ABS, 0.8 mm for PLA, around 2mm for very flexible materials). **How I Designed This** I used FreeCAD v17 - ubuntu daily build. Mainly Part Design NEXT with reference planes for robust design (no importing of external geometry in the sketcher). Draft WB for positioning. Fastener WB for well, fasteners (bolts, nuts). Thanks to all that make FreeCAD possible. You are great!

With this file you will be able to print Protohead V7 "Zeus" - E3D v6 Full + E3D Titan for FABtotum with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Protohead V7 "Zeus" - E3D v6 Full + E3D Titan for FABtotum.