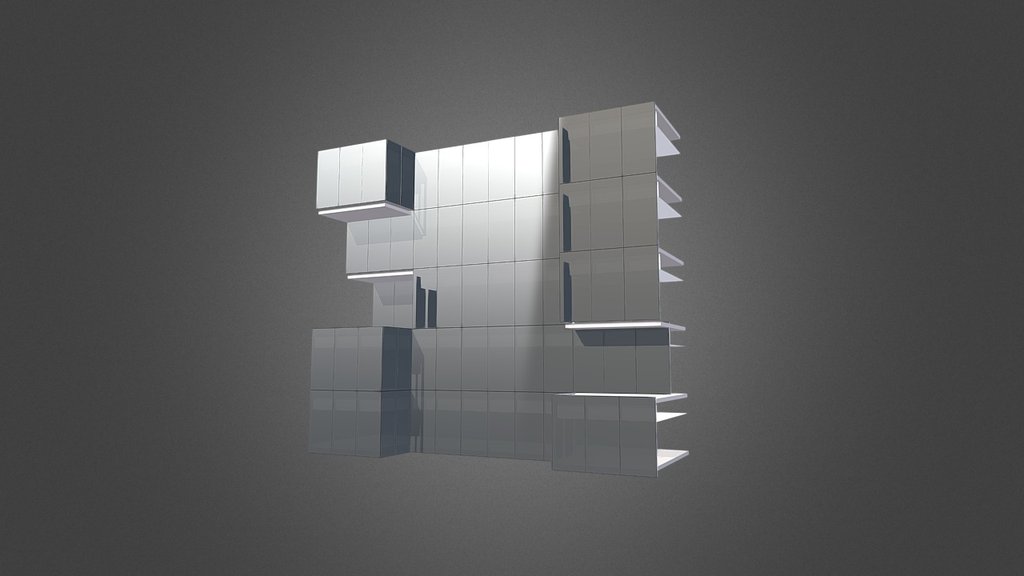

Projecting & Recessive Curtain Wall

sketchfab

Designing a more efficient curtain wall system requires addressing several drawbacks to traditional curtain wall panels. Traditional panels are often prone to water intrusion at joints and seams, where wind-driven rain can easily seep through gaps between adjacent panels. This issue is frequently exacerbated by the use of sealants that deteriorate over time, losing their effectiveness in preventing moisture entry. Additionally, the weight and structural support requirements for traditional curtain wall systems can be substantial, particularly when high-performance glass or other heavy materials are specified. This added load often necessitates a more extensive structural system, which can increase construction costs and project timelines. Another limitation of traditional curtain walls is their relatively low thermal performance. Insulation within the panel cavities may not be sufficient to meet modern energy efficiency standards, leading to increased heating and cooling loads for buildings. Furthermore, the maintenance needs of traditional curtain wall systems can be substantial due to the numerous components involved, including frames, glazing, and sealants. Regular inspections and repairs are essential to prevent water damage and ensure ongoing performance. Overall, these issues highlight the need for more advanced curtain wall solutions that prioritize water-tightness, structural efficiency, and thermal performance while minimizing maintenance requirements.

With this file you will be able to print Projecting & Recessive Curtain Wall with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Projecting & Recessive Curtain Wall.