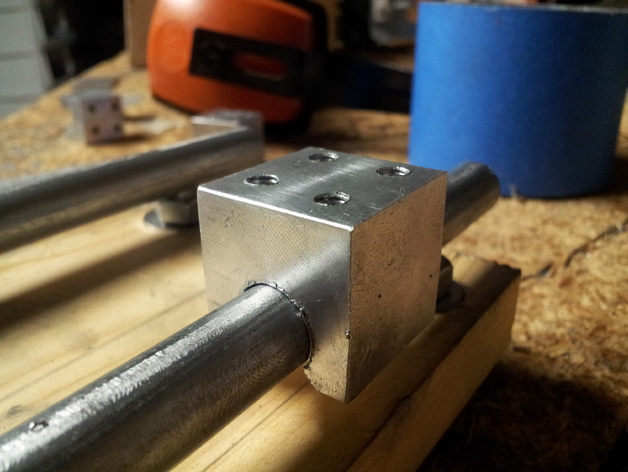

Printed jig for metal CNC bearing

thingiverse

It's vital to have a robust linear rail system in place if you ever aim to cut through thick metal with your CNC mill. Unfortunately, professionally made bearings can be prohibitively expensive. Many makers in the past have devised ingenious methods to fabricate their own railing from 1/2" steel rods found at hardware stores, but none have yet attempted to craft their own bearings to my knowledge. I've designed a jig that you can print out to do so. The jig can be wrapped around a 1" aluminum cube, allowing guide holes to be drilled for the screws and bushing. To build an entire CNC machine, you'll need 12 of these jigs, which translates to approximately 1 foot of 1" aluminum bar stock. You can find this on Amazon for less than the cost of a single 4-pack of bearings. Download and print bearing-jig.stl. Wrap the jig around a 1" (30mm) aluminum cube. Cut such a cube from 1"x1" (30mm x 30mm) aluminum bar stock. The length doesn't matter as long as the sides are orthogonal to each other and can rest securely in the jig. Place the jig in position and drill five holes of varying diameters: 1-3mm, corresponding to the holes on the jig. Switch out your drill bit and enlarge these holes to 4mm using an M5 or 10-32 tap to thread the four bottom holes, enabling you to connect the bearings to a board. Enlarge the remaining hole to 1/2" (12mm) in size. You might need multiple drill bits for this task. After the hole is drilled, use a saw to remove a 3/8" (10mm) section from the thin wall that forms while drilling. File the surrounding areas as needed until the bearing can glide smoothly along a 1/2" supported linear rail.

With this file you will be able to print Printed jig for metal CNC bearing with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Printed jig for metal CNC bearing.