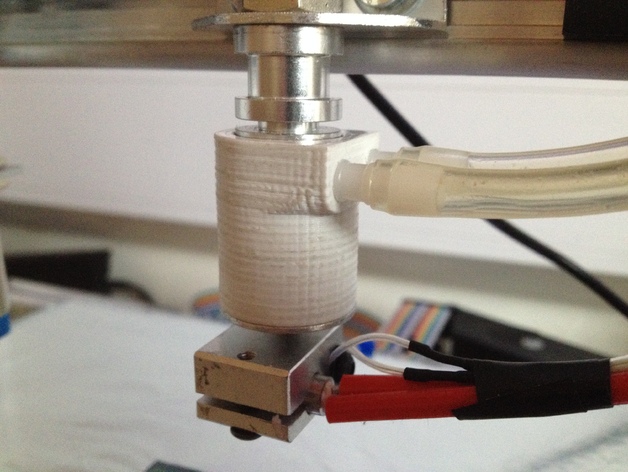

Printable water cooling jacket for v6 type hotends.

thingiverse

As the name says, this is a printable jacket to convert v6 type hotends to water cooled. The name reveals the primary function of the product. The aluminum heatsink seals with two O rings allowing adjustment of outlet pipe placement which helps with disassembly. The jacket conceals the printed material behind the final cooling fin to prevent damage from the heat block and maintains its cool temperature with a separate coolant system, providing increased insulation between these components if required. Principally, keeping the filament cool will maintain self-cool temperatures necessary for operation. This is best suited for use in enclosed printers experiencing high internal ambient temperatures or running filaments requiring higher operating temperatures than typical materials require, usually around 50 degrees. Users should also note that this cooling system's performance would remain effective even if using hot water just above freezing temperature, depending on how it will be configured. Or they may want to consider applying multiple-head printer configurations for an increased need reduction from extensive fan operation, but not required necessarily. The intention of the product design was to allow anyone with minimal equipment or technical experience can create their own, by making use of available computer aided design files (.stl file type), as long as users pay close attention during manufacturing procedures. For optimal leak protection, manufacturers are recommended ensure everything gets made exactly in specified dimension tolerances - clean-up work after this printing task isn't too out of the question, and will likely be required in order to finalize their results. Updates/changes implemented for previous iterations: The .stl file associated with a certain v6 type was replaced, now named correctly "v6_jacket_v3.stl" while older file uploaded was incorrectly shortened by 1.25 mm. It seems this edit went unseen as no other comments were registered in regards to the discrepancy before correction took place - it does provide better compatibility though because these sorts have higher demands when running hot filaments so might appreciate slightly improved designs. Larger versions can also fit upon modified setups for a printer referred to "k8200". Still not fully confirmed but details shared with other designers who can verify this new variation. Special printing tool instructions available within document provided here which may address questions not thoroughly discussed below: Assembly guide steps: Step 1-2 Using DXF files included you'll know where those pipe and fitting marks should be placed accordingly because if using an ordinary 20 x18 O-ring (with appropriate materials, preferably the softer types such as "red ones"), simply align them properly at correct locations shown before sealing into position. If good quality prints allow printing spigots or adapters that could connect tubing without further action. However I've used only regular half-cut pipe couplers from local supply shops & stuck them together afterward after successful fitting in the hole created during 3D print process (all with relative ease) and no leaks were seen when sealed tightly afterwards - all based off my findings alone. You'll also find information provided elsewhere regarding necessary cuts & grinding work needed prior assembling components mentioned above including details about certain specifics involving heat sinks where adjustments will take place; especially for ensuring successful outcome so follow every point very closely throughout procedure to avoid mishaps due carelessness resulting severe injury even possible total system failure thus causing significant economic damage. This water cooled conversion v6 jacket requires no expertise to build however be cautious and check its safety first before running tests or making modifications because you might unknowingly damage critical electronics due carelessly applied electrical wiring under normal circumstances – a reminder frequently made available throughout this particular discussion here. For future updates feel free sharing related knowledge as part shared credit belongs everyone helping bring this project further advancements even after final build completion stage.

With this file you will be able to print Printable water cooling jacket for v6 type hotends. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Printable water cooling jacket for v6 type hotends..