Print Rite DIY 3D Printer - Adapter MK2 MK3 Heat Bed

thingiverse

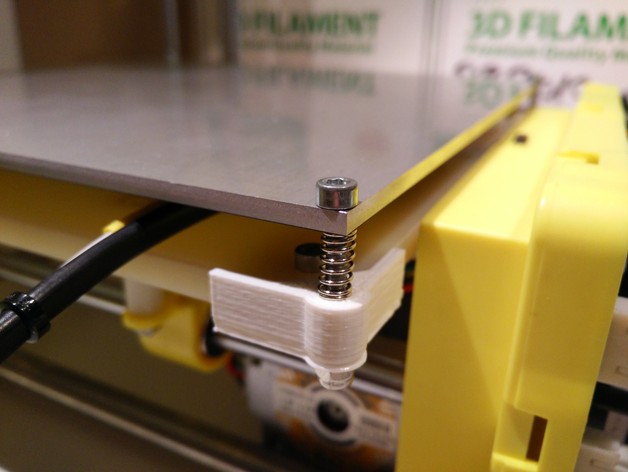

It's an adapter for the MK series Heatbeds and the Print Rite 3D Printer. Original bed is 21 x 21 cm; MK3 bed is 21.4 x 21.4 cm. To involve cutting 1cm from the corners of the original Acrylic bed, which I'll be able to post pictures for later on. On November 27th, I already printed out the part with M3 screws going through nicely. I will prepare the original bed and set the screws while making some more pictures to confirm the design. Everything is in place, and the part has been validated. The next day, I got the new 12V - 15A PSU. We'll see how it goes. On November 28th, Z-axis stopper screw is too small; you'll have to use an M5 x 80mm one. I designed a part for better stability and work it nice with added nuts. On December 1st, the new PSU was connected (12V - 15A). After 18 minutes, I reached 100°C and tried to get 13V out of it to reach 110°C, but didn't manage to print on bare aluminum surface. Hairspray needed to be applied for a grip. I got very light warping with ABS at 100°C heatbed, while PLA corners held the 100°C fine, not letting the heat propagate downwards so I don't have any worries there. Heatbed spent at least three hours at 100°C and corner parts were okay. On December 3rd, a pot is on my PSU (it's designed for LED stripes 12V-15A) with me setting it so that I got 13V on heatbed connectors. With this setting, I can reach 110°c easily; however, the curve isn't perfect yet as it would struggle. But now it takes only around twelve to fifteen minutes and doesn't show any signs of straggling anymore. With this setting, ABS is not warping anymore at 110°C. And for that, you have to spray some hairspary on the surface and make sure that brim of the part is no more than five mm. On January 14th, I made a new version with adding part like this one(http://www.thingiverse.com/thing:874155)for leveling. However my main problem here was the head inside screw which can be resolved if you give some extra height to that as seen in picture (just kidding! I found much better alternative and have shared pictures so we see for ourselves!). So check out pictures please! On January 14th, I went back and had another look. On my last note regarding print settings I have to admit this still doesn't do everything for me since Print Rite has such high resolution options so that's always up there on your priorities too. Also important is having a strong print layer because it gives very fine prints as long they can handle high pressure with ease which leads people getting more and more into additive printing (additive manufacturing technology or even industrial grade machines), however in home users have not the luxury, which makes hobbyists love this new form factor all around; especially when they combine with the likes.

With this file you will be able to print Print Rite DIY 3D Printer - Adapter MK2 MK3 Heat Bed with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Print Rite DIY 3D Printer - Adapter MK2 MK3 Heat Bed.