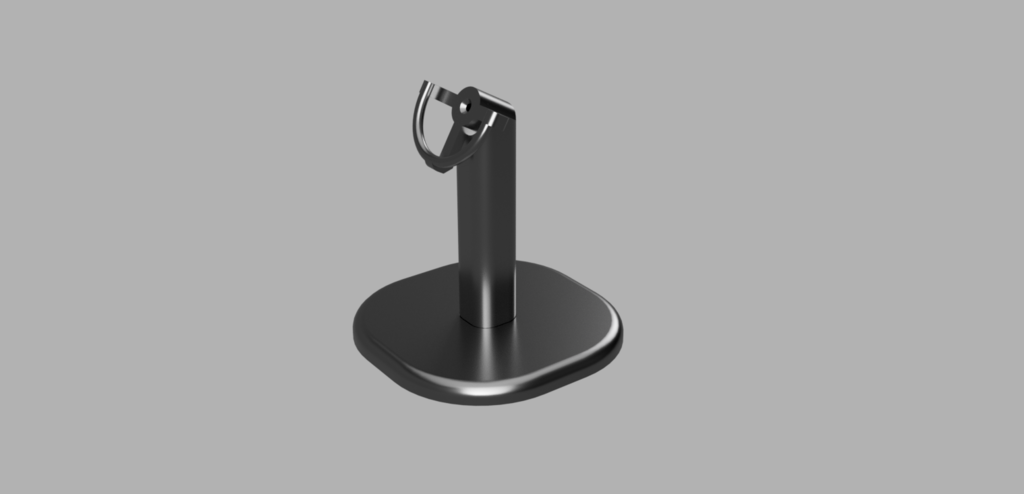

PopSocket Modular Mount

thingiverse

<H1>Modular PopSocket Mount</H1> I designed a custom PopSocket mount because I couldn't find one that suited my needs. This design works for both my phone and car, so if it doesn't fit your device, please let me know and I'll make adjustments to make it more universal. <h2><b>Phone Stand Requirements:</b></h2> To assemble the phone stand, you will need: * 1x PopSocket Stand Base * 1x PopSocket Stand Pole (30/40 degrees) * 1x PopSocket Mount * 1x M3x20mm slotted screw * 1x M3 nut * 1x 4.2x32mm slotted wood screw If you need a longer or shorter PopSocket Stand pole, simply download the STEP file and edit it to your liking. <h2><b>Car Mount Requirements:</b></h2> To assemble the car mount, you will need: * 1x PopSocket Car Mount * 1x PopSocket Mount (or PopSocket Mount + Support if using PopSocket Mount Arm Support) * 1x M3x20mm slotted screw * 1x M3 nut Optional components include: * 1x PopSocket Mount Arm Support * 1x PopSocket Swivel Ball Mount Thread * 1x Popsocket Swivel ball Mount nut * 1x PopSocket Swivel Ball Mount Ball * 2x 1.5x15mm steel wire * 1x M3x20mm slotted screw * 1x M3 nut If you need a longer or shorter PopSocket Mount Arm Support, simply download the STEP file and edit it to your liking. <h2><b>Print Settings and Orientations:</b></h2> I've used PLA for my prints and found them to work well in my climate. However, I recommend using PETG or a similar material to prevent deformation. Here are the print settings I used: * PopSocket Mount: Printed flat with support everywhere and brim, solid, lowest resolution * PopSocket Mount + Support: Printed flat with support everywhere and brim, solid, lowest resolution * PopSocket Mount Arm Support: Printed solid * PopSocket Stand Base: Printed flat with 25% infill, any resolution * PopSocket Stand Pole: Printed standing at 20% infill, any resolution * PopSocket Swivel Ball mount ball: Printed standing at 25% infill, lowest resolution * PopSocket Swivel Ball Mount Nut: Printed standing with the flattest surface down at 25% infill, lowest resolution * PopSocket Swivel Ball Mount Thread: Printed standing with the flattest surface down at 25% infill, lowest resolution * PopSocket Car Mount: Printed sideways at 25% infill, any resolution (lower is better) I recommend using at least 4 top/bottom layers and 5 walls. <h2><b>Update 05.07.2020:</b></h2> I've added the following updates: * A new PopSocket Mount with support for an Arm Support * PopSocket Arm Support * STEP file for PopSocket Arm Support * Tweaked PopSocket Car Mount to fit 1.5mm steel wire, preventing the PopSocket Swivel Ball mount Thread from turning * Tweaked PopSocket Swivel Ball mount Thread to fit 1.5mm steel wire <h2><b>Update 15.06.2020:</b></h2> I've made the following updates: * Updated file names and STL files * Fixed wall thickness on PopSocket Swivel Ball Mount Nut * Made small tweaks to Popsocket Swivel Ball Mount Thread * Fixed PopSocket Pole angles * Added STEP file for PopSocket Stand pole 30/40 degrees, allowing you to edit the length to your liking <h2><b>Future Plans:</b></h2> I'm planning to add the following features: * Dash mount * <del>Support mount to prevent phone rotation in car</del> * Articulating arm * Tripod mount * Bike cycle mount If you have any other ideas for mounts, please let me know and I'll do my best to create them!

With this file you will be able to print PopSocket Modular Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on PopSocket Modular Mount.