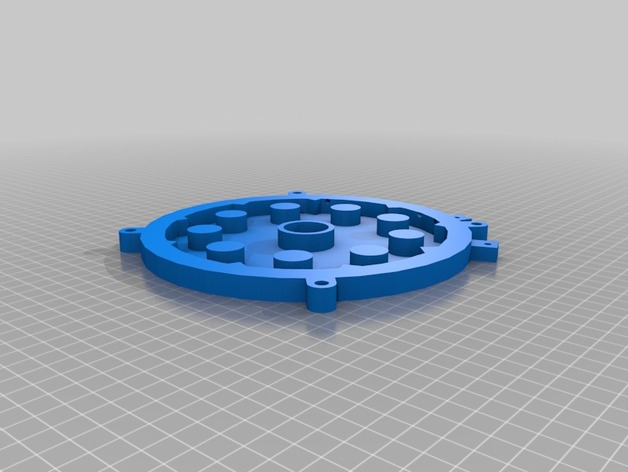

PMA Permanent Magnet Alternator

thingiverse

This is a comprehensive guide to designing and printing an Electromagnetic Device (EMD) using 3D printing. The project involves creating several components, including the casing, magnet plate, coil plate, and rectifier, which require different strengths, stiffnesses, and warping properties. **Component Requirements:** 1. Casing: Should be printed with 30% infill and 4 layers of walls to ensure structural integrity. 2. Magnet Plate: Can be printed with 20% infill due to PLA's rigidity. 3. Coil Plate: Needs to be printed at 30% infill to resist warping caused by the resin. **Alternative Materials:** 1. Colorfabb XT: A viable alternative to PLA for components that require high strength and resistance to heat. **Printing Recommendations:** 1. Use colorless PLA or XT for the coil plate, as it will be exposed to resin and direct sunlight. 2. Use a wire grove in the winder to hold the wire tight during winding. 3. Increase the recess on the O Ring by 1/16 of an inch for a secure fit. **Component Changes:** 1. Wall diameter increased to accommodate recessing the O-ring. 2. Magnet plate size adjusted for perfect fit with magnets and reduced need for epoxy. 3. Coil plate dimensions matched with casing wall thicknesses. 4. Terminal bolt holes added for attaching wires. **Future Plans:** 1. Create printable spacers to limit movement on the rod. 2. Print case STLs without a mounting plate. 3. Experiment with low fill pieces for fit checks.

With this file you will be able to print PMA Permanent Magnet Alternator with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on PMA Permanent Magnet Alternator.