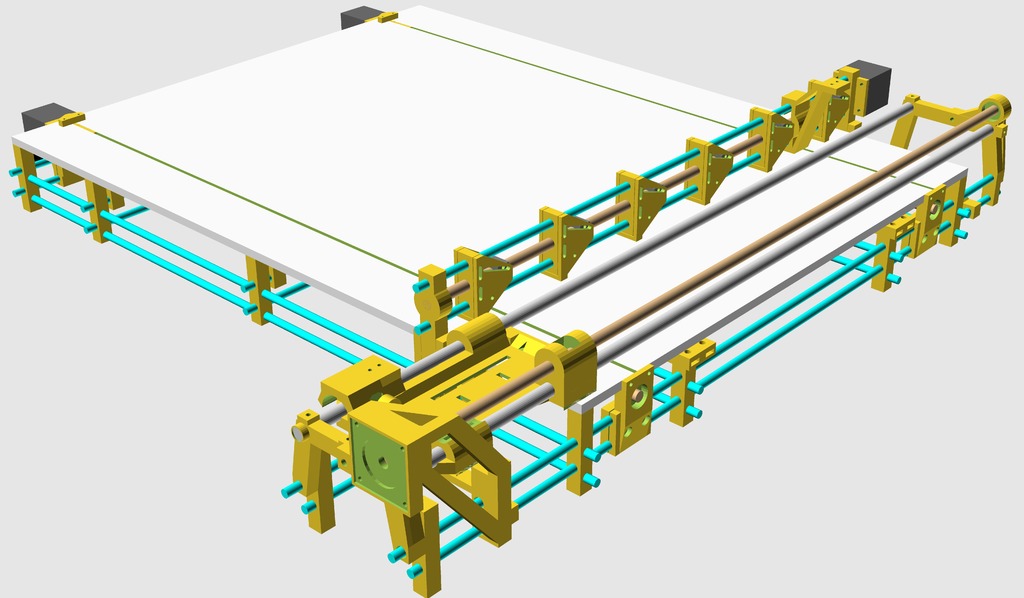

Plate Saw Machine

thingiverse

### Summary This project focuses on designing and controlling a Plate Saw Machine, with all details available on GitHub at "https://github.com/VirToReal/VirToCut". A YouTube video explaining the project can be found here: https://youtu.be/xQ6T13urcc0. ### What is this? The Plate Saw Machine is an automated cutting tool that creates straight stripes from a plate. It can be controlled manually or automatically through software, with adjustable saw blade distance and material feed speed. The thickness of the saw blade is added automatically in manual mode. To control the saw via software in automatic mode, users can use a custom code syntax: >> A50 B300 // Feed Material 50mm and cut into that material 300mm. >> A50 B300 >> A30 B300 >> A30 B300 >> A10 B300 >> ROTATE // Saw stops, user have to rotate the plate 90°, some visual assistance shows user which stripes have to be placed into the machine (not ready yet) and confirms via software/hardware-button. >> A100 B100 >> A100 B100 >> WAIT // Saw stops, user have to place a new pair of stripes into the machine and confirms to proceed. >> A80 B60 >> A80 B60 >> WAIT // Saw stops, user have to place a new pair of stripes into the machine and confirms to proceed. >> A50 B20 >> A50 B20 >> A50 B20 The result can be seen in the graphic provided. To press the plate onto the workbench, a structure was constructed that does this for you if you select the right material from a drop-down menu. ### Generating dynamical Structures Users can generate their own components using the "ConstructionTemplate.scad" file with OpenSCAD (http://www.openscad.org). Every component is adjustable in its dimensions as described in the “OpenScadDokumentation”-Folder. In OpenSCAD, users can switch between the complete overview and each single printable part by using the “printmode"-Variable within the “ConstructionTemplate.scad” file. ### Necessary Skills To get this project to work, you need some experience with 3D printing and electrical engineering skills to create a PCB and wire up a power supply, Raspberry Pi, Arduino Mega 2560, and RAMPS shield. The files for milling/etching the PCB are in the "KiCad"-Folder, which can be edited using KiCad Software (http://kicad-pcb.org). FlatCam (http://flatcam.org) was used to mill the Gerber files from KiCad. ### Software The Python software sends G-Code commands from the Raspberry Pi to the Arduino over a serial interface. Marlin (http://marlinfw.org) runs on the Arduino, interpreting received G-Code commands and driving the engines with the RAMPS1.4 Shield (http://reprap.org/wiki/RAMPS_1.4). The Python software can be found in the "Python Software"-Folder, currently available only in German. ### TODO While the project is mostly complete, some smaller improvements still need to be made: - A structure on the material feeder that prevents the material from rotating. - Some minor software updates (time constraints are a challenge).

With this file you will be able to print Plate Saw Machine with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Plate Saw Machine.