Planet Gearbox for Fine Mirror Adjust, parametric

thingiverse

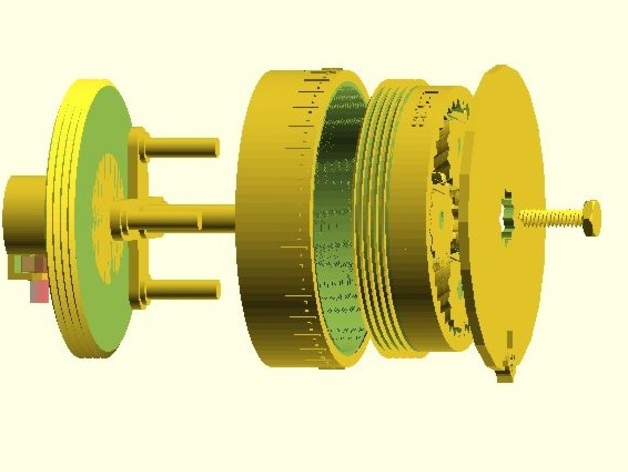

Human: Version 1.1\nAdjusting mirrors or beamsplitters on an optics bench can be quite challenging. This device sits between the mirror and the mounting post, making it easier to make fine adjustments with a 5.33:1 gear ratio, resulting in 2 degrees of mirror motion for every 10 degrees on the dial.\nThe gearbox consists of 5 parts: a captured planetary gear system (with herringbone teeth); a dial; a planet-gear carrier; a mounting post holder; and a threaded connector ring. The entire set is printed at once, then assembled. The connector ring holds the carrier between the gearbox and the post-holder.\nTo use this device, simply insert the Planet-carrier into the bottom, sandpaper the 5 posts to get them to slide in smoothly, and gently thread the post-holder into the connector to hold the Planet-carrier in place. Then, thread the connector onto the gearbox to cover the threads.\nOPTIONAL Metal Hardware\nI have included 3 optional metal bolts and 1 nut (colored pink in OpenSCAD view):\n1)The post-holder has a set-screw and nut for tightening it up on the post. #4-40 (M3) with nut work nicely,\n2)The output shaft has a threaded hole for bolting on the mirror/beam-splitter optics equipment.\n3) The Planet-carrier has a threaded hole for a #4-40 (or tinier!) woodscrew that can provide a low-friction pivot up against the post-holder it it needs to be screwed on more tightly. I've been backing off a quarter turn on the post-holder assembly and that seems to make the friction tolerable without a pivot.\nHow I Designed This\nPlanetary gear design\n There are 3 gears in a planetary gearbox: Sun, Planets (riding on a carrier), and Ring. Any one of them can be held fixed, and the other two become an input/output pair. This provides no less than 6 gear ratios. If two gears are fixed, then the system behaves as a 1:1 (a feature used in automatic transmissions).\nFormulas for teeth and gear ratios can be derived by considering the ratios of circumferences of the gears or downloaded from the internet--they are also displayed in the OpenSCAD program. The biggest gear ratio is obtained when the Ring is fixed, the Sun is input, and the Planet-carrier is output. \nHowever, the Planets are in-between the Sun and Ring. So to make this accessible, the carrier has an output shaft that comes up through the Sun gear. This shaft is threaded for a bolt that attaches to the optics mirror/beam-splitter. But since most designs drive the Sun gear with an interior shaft, I had to use a sun driver on the outside of the Sun gear teeth, which is where the dial snaps on.\nTo keep the carrier friction low, I made the Planet-carrier posts as skinny as possible, and put 1mm friction rings (bearings) on the bottom of the posts. In operation the carrier is held in place by being sandwiched between the post-holder and the gearbox.\nAt larger gear ratios, the Sun gear shrinks, making the output shaft very skinny. Using the 2" (51.7mm) gearbox diameter, I was able to get a 3.7:1 ratio using a 1/4-20 (M6) bolt, a 5.33:1 ratio using a #6-32 (M4) bolt, and a 6:1 ratio using a #4-40 (M3) bolt. For the smaller bolts, I also had to reduce the number of Planets from 5 to 4 to 3, otherwise the planet teeth overlapped. I've also made a 3" gearbox with #4-40(M3) bolt that achieved 1:9.8 for all you extreme gearheads out there. Larger diameter gear boxes should be able to get even higher gear ratios. If higher gear ratios are needed a 2nd set of gears will be needed, this design uses only one planetary gear set.\n\n \n \n Update Log\n10/22/2016 Added a 1:9.8 gear ratio, 3" (77.4mm) gearbox, which pushes the limit of torque possible with thin PLA shafts.\nThe connecter ring now has 10-deg tick marks for helping align, and the logo scales with size.\n10/21/2016 Fixed some bugs in the .scad file, now it displays "fake threads" correctly, and warns not to print. If unintentionally printed, however, the parts may still be assembled.

With this file you will be able to print Planet Gearbox for Fine Mirror Adjust, parametric with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Planet Gearbox for Fine Mirror Adjust, parametric.