PLA Welding: Join PLA like a boss

thingiverse

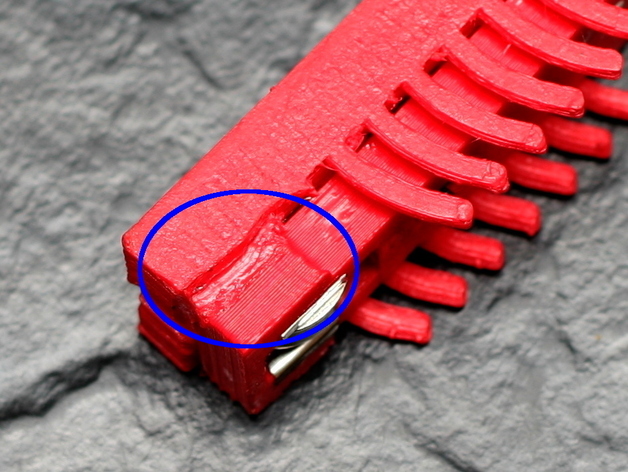

Cyanoacrylate super glues are ineffective on PLA; epoxies may be a hassle with long setting times and reduced strength compared to the rest of the part. Hot air tools often melt too much material, making it difficult to achieve good joints and unable to fill gaps. To create a strong, lasting joint, use a soldering iron to weld pieces together, employing filler rod as required. To prepare for this, set your extruder temperature to its maximum limit, move the bed out of the way (ideally over a disposal area), and purge 5-6 inches or 12-15 cm of filament (commonly referred to as "purge" in your host software). You may only need to purge a few millimeters of 3 mm filament. Cool the extruded filament by blowing on it, if necessary (a fan is preferable). Repeat this process about a dozen times. For joining PLA pieces, acquire an old or cheap soldering iron with high wattage (around 40W) and a blunt, damaged tip that's no longer suitable for soldering. Position the filler rod alongside the joint and run the soldering iron over it, melting both the rod and a small amount of each part to be joined. For larger gaps, repeat with more filler rod. This method results in joints as strong or stronger than the printed part, effectively fills gaps, and provides precise control over the melted material.

With this file you will be able to print PLA Welding: Join PLA like a boss with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on PLA Welding: Join PLA like a boss.