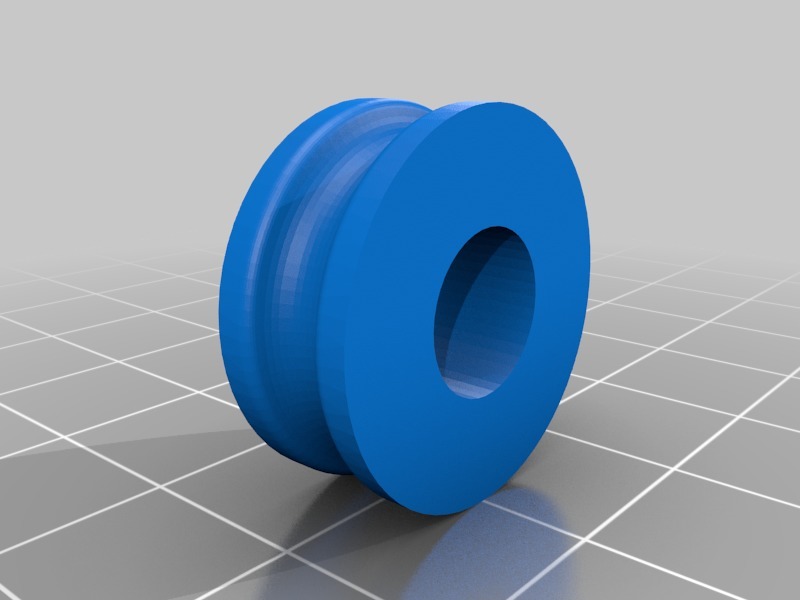

Pipe bender guide for 4mm tubing

thingiverse

Model Engine Fuel Tank Tubing Bending Guide: Mastering 4mm Brass and Aluminium Tube Bending Techniques Are you ready to take your model engine fuel tank projects to the next level? With this comprehensive guide, you'll learn how to bend 4mm brass or aluminium tubing like a pro. Whether you're an experienced hobbyist or just starting out, our expert tips and tricks will help you achieve perfect bends every time. **The Basics of Tube Bending** Before we dive into the nitty-gritty of bending techniques, let's cover some essential basics. Tubing is typically made from brass or aluminium alloys, both of which are popular choices for model engine fuel tanks due to their durability and resistance to corrosion. When selecting tubing, make sure to choose high-quality materials that meet your project's specific requirements. **Choosing the Right Bending Tools** To bend 4mm tubing effectively, you'll need a few specialized tools. A tubing bender is the most essential tool in your arsenal, but you may also want to invest in a tubing crimper and some safety gloves for added protection. When selecting a bender, consider the type of tubing you're working with and the desired bend radius. **Bending Techniques 101** Now that we've covered the basics, it's time to get hands-on! Here are some fundamental bending techniques to master: 1. **Simple Bend**: This is the most basic bending technique, where you create a smooth, continuous curve in the tubing. 2. **Elbow Bend**: Create an elbow-shaped bend by rotating the tubing 90 degrees and then continuing the curve. 3. **Kinked Bend**: Achieve a kinked or zig-zagged shape by making multiple small bends in succession. **Tips for Achieving Perfect Bends** To ensure that your bent tubes are flawless, follow these expert tips: 1. **Use the right amount of pressure**: Apply gentle yet firm pressure to avoid damaging the tubing. 2. **Maintain a steady hand**: Keep your hands steady and controlled throughout the bending process. 3. **Monitor temperature**: Avoid bending in extreme temperatures, as this can cause the tubing to become brittle or prone to warping. **Troubleshooting Common Issues** Don't worry if things don't go according to plan – we've got you covered! Here are some common issues and their solutions: 1. **Tubing kinking**: If your tubing is kinking, try adjusting the bender's jaw pressure or using a different type of bender. 2. **Bend radius inconsistency**: To achieve consistent bend radii, use a tubing template or consult a bending chart. **Conclusion** With these expert tips and techniques, you'll be well on your way to mastering 4mm brass and aluminium tube bending for your model engine fuel tank projects. Remember to always follow safety guidelines and invest in high-quality tools to ensure professional-grade results. Happy building!

With this file you will be able to print Pipe bender guide for 4mm tubing with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Pipe bender guide for 4mm tubing.