PARKSIDE PGS 500 A1 to CNC

thingiverse

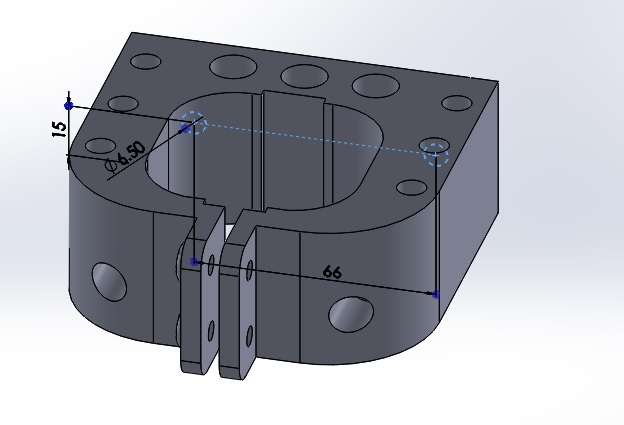

Converting the PARKSIDE PGS 500 A1 to a Computer Numerical Control (CNC) machine involves upgrading its functionality and precision. The process requires expertise in both mechanics and electronics, as it demands a deep understanding of how the machine's components interact with each other. Firstly, the mechanical system needs to be modified to allow for precise control over movement and positioning. This includes replacing the existing drive systems with more accurate ones and installing new encoders to track movement accurately. The spindle must also be upgraded to achieve higher speeds and better torque. Electronics play a crucial role in CNC conversion as they enable precise control of the machine's movements. A dedicated CNC controller is installed, which communicates with the computer via a high-speed interface. This setup allows for real-time monitoring and adjustment of cutting parameters, ensuring optimal results. The existing motor drives are replaced with more powerful ones that can handle the increased load of precision cutting. Additionally, advanced power supplies ensure stable voltage levels, reducing the risk of electrical noise or power surges during operation. To achieve precise control over the machine's movements, advanced software is developed to interface with the CNC controller. This software enables users to input precise coordinates and parameters for each cut, ensuring accurate results every time. Finally, a comprehensive testing phase is conducted to ensure that all components are functioning as expected. The machine is put through various tests to verify its precision, speed, and overall performance.

With this file you will be able to print PARKSIDE PGS 500 A1 to CNC with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on PARKSIDE PGS 500 A1 to CNC.