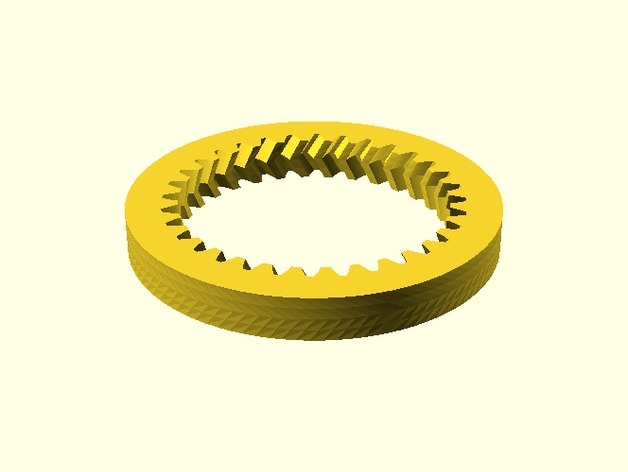

Parametrisches Pfeil-Hohlrad / Parametric Herringbone Ring Gear

thingiverse

Parametric Herringbone Involute Ring Gear Creates a herringbone ring gear without profile displacement. A ring and spur gear mesh if they have the same module and opposite helix angles. Herringbone gears run more smoothly than gears with straight teeth. They also do not create axial load like helical gears do. A helix angle, if used, should be set between 30° and 45°. Recommendations for the helix angle depending on the module can be found in DIN 3978. This script adjusts the pressure angle in the transverse section to the helix angle: e.g. with a 30° helix angle, a pressure angle of 20° becomes a pressure angle of 22.80° in the transverse section. Format: pfeilhohlrad(modul, zahnzahl, hoehe, bohrung, eingriffswinkel, schraegungswinkel) Parameters: modul = gear module zahnzahl = number of teeth hoehe = gear height randbreite = width of the rim around the ring gear, measured from the root circle bohrung = central bore diameter eingriffswinkel = pressure angle, standard value = 20° according to DIN 867 schraegungswinkel = helix angle to the rotation axis; 0° = straight teeth

With this file you will be able to print Parametrisches Pfeil-Hohlrad / Parametric Herringbone Ring Gear with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Parametrisches Pfeil-Hohlrad / Parametric Herringbone Ring Gear.