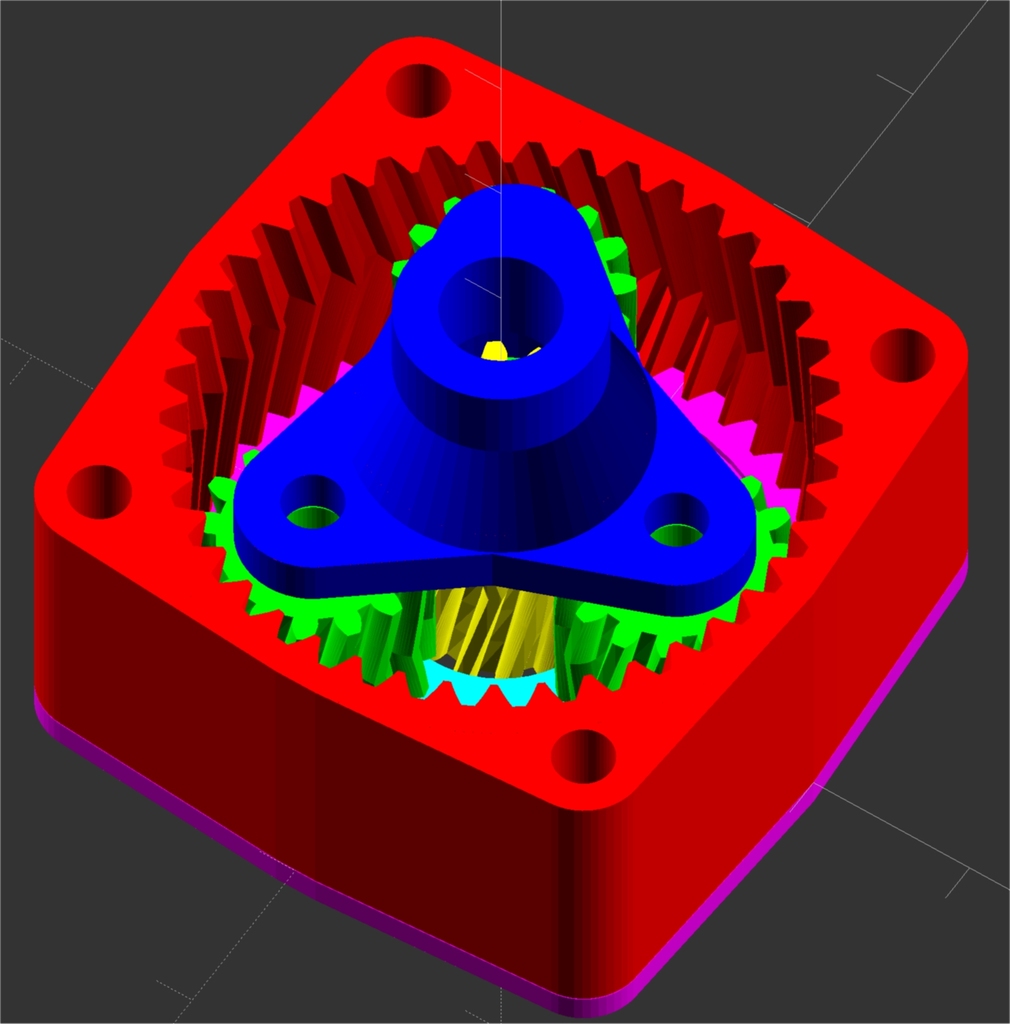

Parametric Epicyclic Gearbox. Helical Support.

thingiverse

A high-performance parametric gearbox generator has been upgraded to support complex helical spur gears. To print all components simultaneously, use a separate program to combine them. This is not a print-in-place setup! The author utilized ReplicatorG to adjust the models for optimal printing and Blender to merge all components into a single file. As with previous posts, this design has been thoroughly tested. The included STL files are for the NEMA17 gearbox used in testing, which revealed that it prints smoothly with a 0.4 mm nozzle when lubricated with autosol chrome polish for several hours before assembly. Once quiet operation is achieved, clean and grease the components. Required hardware includes three 3mm diameter, 18 mm shafts for the planet gears, M3 screws to secure them to the NEMA17 motor, and six washers - one above and one below each planet gear - to separate them from the carrier. The main objective was to determine if helical gears are quieter than traditional spur gears. The results indicate that they are not significantly quieter with this specific design, making it uncertain whether the added complexity is worth the effort. A simpler solution might be to use an existing design like https://www.thingiverse.com/thing:2410859. A small update reveals that a comparison between the two gearboxes showed the helical model to be quieter at around 150 RPM input speed, leading to plans for testing a DblHelixTwist = 80 version next.

With this file you will be able to print Parametric Epicyclic Gearbox. Helical Support. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Parametric Epicyclic Gearbox. Helical Support..