Paper Pulp Printer Extruder

myminifactory

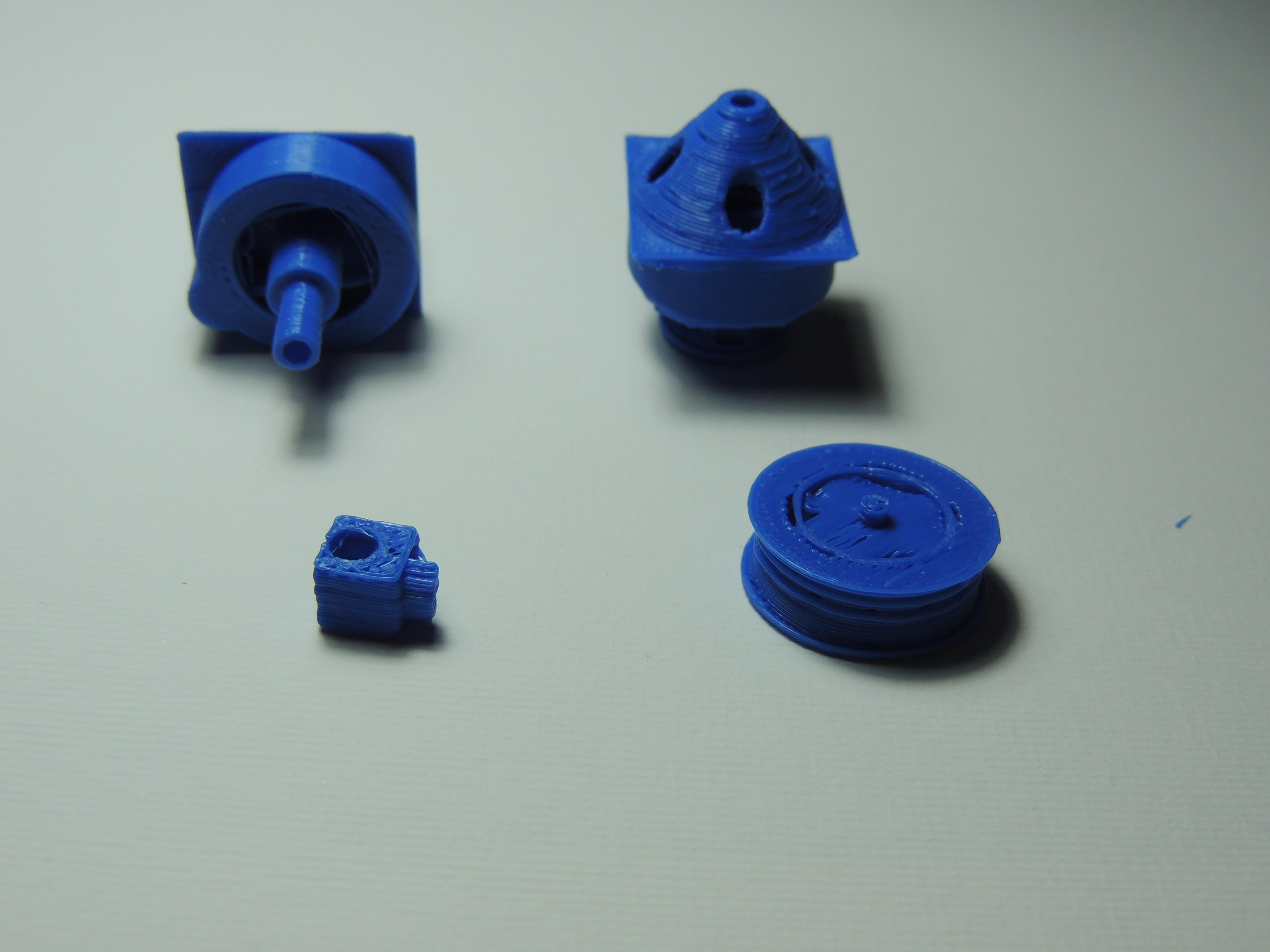

A paper-making machine has been designed to create a 10mm strip of paper pulp that rolls around and around to build up a three-dimensional object. The extruder part takes in water and pulp, then sucks out the water and air, rolling the paper pulp layer onto its surface. This is a true mini-factory; it's mine (and shared with you), it's mini (or even micro) and it certainly makes paper. This design has not been tested. It's published to ensure I don't lose the files, as happened earlier, and partly because there's a competition with a mechanical category. Paper-making machines can be huge; this machine is about 72mm tall and 32 x 21 mm cross-section. For our paper extruder, paper fibres enter through a tube (3mm ID) into the central hole, then through a 2mm nozzle onto the sieve, which is a wheel with a mesh tread. As it moves forward, the wheel presses the paper pulp onto the surface where it sticks. We use active suction on the inside of the rolling sieve to remove water from the inside of the wheel and drag air as well. At the top are four tubes for plenty of flow of air and water out of the extruder head. The designed operation of the rolling sieve wheel is like a caster wheel, skidding slightly around corners but still rolling in the direction of movement. This requires a 'fixed' part at the top with all tubes and a rotating part that turns about the vertical axis while allowing flow of paper fibres in and out. This is undoubtedly the smallest paper-making machine ever built. I had to figure out the suction mechanism, finally using a 12V bilge pump with a venturi on the flow line. The flow line from the pulp tank needs a solenoid to control the flow. And I haven't completed the GCODE interpreter yet. To make paper, you start with a suspension of paper fibres in water at around 4gm/l to 12gm/l. This suspension is run out onto a sieve to catch the fibres on top and let the water fall through, often assisted by suction. In a paper mill, this process is continuous using a large number of rollers based on the Foudrinier machine. Hand-making of paper involves carefully taking off the wet sheet of pulp from the sieve (called a mold) onto a fabric base (traditionally felt), squeezing out excess moisture, then hanging up each felt with its sheet of paper to air dry. Paper pulp can also be called paperclay or even paper mache. However, paper mache can refer to sheets of paper glued together. A single sheet thickness of paper pulp can take several days to air dry, so a thick object needs plenty of time to build and dry enough not to rot on the inside. Anyone have an idea for a paper dryer and mechanism to follow behind the extruder? Does anyone else use paper in a 3D printer? MCOR has printers that work with stacks of paper, cutting each sheet for that layer (see mcortechnologies.com). They can also apply colour as they go, which is unique among known 3D printing methods using paper. I'm working on making a 3D printer that can print room-sized or house-sized objects (see hackaday.io/project/13420-rigtigs-big-3d-printer). I avoided materials like concrete and clay because of the difficulty in dealing with failed prints. Concrete is too heavy for normal suspended flooring to support when printing large objects. I wanted something that could be recycled easily, was not too heavy, was cheap (like free) and yet be made quite large. In a presentation at a makers' place several years ago, one audience member offered 10 tonnes of waste paper per week, delivery in the metro area free (but I respectfully declined). I'm still using what comes through my letterbox. More to do I am slowly moving the greater project forward. However, if you want to have a go yourself, please let me know if you need any clarifications. And everyone, including me, will love to see how you go. Please share this project with others (well, at least those who are crazy enough to tackle a whole new 3D printing material).

With this file you will be able to print Paper Pulp Printer Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Paper Pulp Printer Extruder.