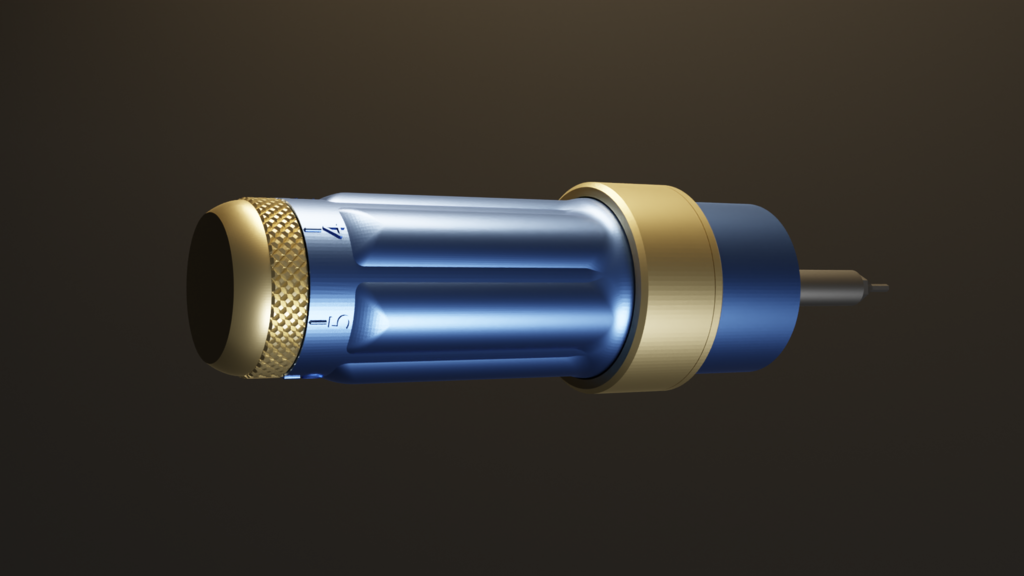

Overcomplicated Variable Torque Wrench Ratchet

thingiverse

REMEMBER: do not leave torque wrench in preload state. Always unscrew cap to 0 position or below when not in use. It's essential practice using torque wrenches. https://www.youtube.com/watch?v=1IdMfdTlHlc https://www.youtube.com/watch?v=MgViZ1Y7NjA As most of my printed parts use M3 hex screws, I got tired of using hex L-key. So, I decided to make a torque wrench for light use. With default 1.8mm thick spring (parametric spring), it works in the range of 0.39 - 1.06Nm (depending on PETG manufacturer, spring stiffness will vary). You can switch springs if needed to change Nm range. I designed variable thickness springs (lofted springs) across its length which gives a wider range like example 0.5-2.5Nm. Included a bunch of various thickness springs. I tested torque wrench mechanism; it can withstand 3Nm+ load, but since I added ratchet mechanism later, I hadn't a chance to test it. Probably it is a weaker point and might break at that point. I doubt anyone needs so much torque, with 3.5Nm, I squished 3D printed part and ruined M4 screw itself. Wrench uses 3x 6000ZZ 10x26x8mm bearings, 2x M3 50mm buttonhead bolts, and 2x M3 nuts; everything else is 3D printed. This tool is probably useless for most makers as it is pretty bulky, but I hope someone will make some use of it. This is the second gen of wrench; the first gen was 2 times shorter without wide front but lacked ratchet function. All parts are oriented properly. All parts were printed with 3 perimeters. Spring, Clip, Insert, Cap parts must be printed from PETG. PLA isn't flexible enough, so it's no go for this design. Only Clip and Hex Shank Holder V2 need to be printed with supports (surfaces parallel to bed). Printed without brim: Springs, Pushers, Switch Ring Holders, Switch Ring (mandatory to keep perfect circle at bottom), Teeths, Spacer, Fastener Top, Fastener Bottom. Printed with brim: Tube, Cap. Other optional. 100% infill for teeths and pushers; other parts with 40-70% cubic infill. Top/bottom 5-6 layers. Thin layers or single line extrusion depending on slicer for Clips; otherwise it won't print tail. Turn off this option for Tube; numbers don't generate properly. BOM link: https://docs.google.com/spreadsheets/d/1kFQk56aX42L3CyWq5Kztgkbw85gURGIeB6PzmdoBpio/edit?usp=sharing Feel free to ask. If you found this useful, please donate what you think it is worth to my paypal.me. Help cover the time of design. Thanks; Enjoy!

With this file you will be able to print Overcomplicated Variable Torque Wrench Ratchet with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Overcomplicated Variable Torque Wrench Ratchet.