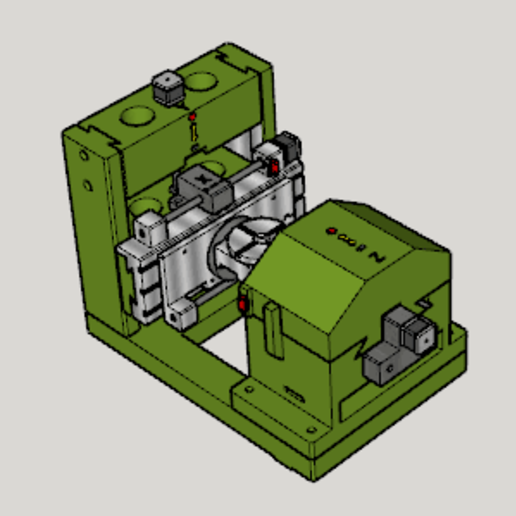

Original CNC 5Axes Mill

cults3d

Five-Axis Milling Machine, High-Precision CNC A five-axis mill is a type of computer-controlled machine tool that uses advanced software to precisely manipulate and control a cutting tool or spindle head for milling operations. This versatile machining center offers an unparalleled level of precision and flexibility in its ability to access parts from multiple angles. With the capability to rotate the workpiece, as well as the cutting tool, around five distinct axes (X, Y, Z, A, and B), it enables users to perform complex tasks with ease. One of the key benefits of a five-axis mill is its capacity for high-speed machining. This allows manufacturers to significantly reduce production time and costs associated with labor-intensive manual processes. Additionally, by minimizing the need for repositioning or reorienting parts, these machines help minimize material waste and optimize surface finish quality. Another advantage of five-axis milling is its potential for increased part complexity. By offering access to multiple axes simultaneously, users can create intricate geometries, complex shapes, and detailed features with unparalleled precision. This makes it an ideal solution for applications in aerospace, automotive, and medical industries where high-precision parts are critical. When selecting a five-axis mill, manufacturers should consider factors such as machine size, spindle power, and axis travel range. They must also ensure compatibility with their existing manufacturing infrastructure, including software systems and tooling. By investing in the right equipment and training for operation and maintenance, companies can maximize the benefits of five-axis milling technology. To achieve optimal performance from a five-axis mill, regular maintenance is crucial. This includes periodic cleaning and lubrication of moving parts, as well as calibration and alignment checks to ensure axis accuracy and repeatability. By adopting these best practices, manufacturers can maintain machine reliability, prevent downtime, and extend the lifespan of their equipment. In summary, a five-axis mill represents a significant advancement in CNC technology, offering unparalleled precision, flexibility, and efficiency for complex machining operations. Its high-speed capabilities, increased part complexity, and potential cost savings make it an attractive option for manufacturers seeking to improve productivity and competitiveness in their industries.

With this file you will be able to print Original CNC 5Axes Mill with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Original CNC 5Axes Mill.