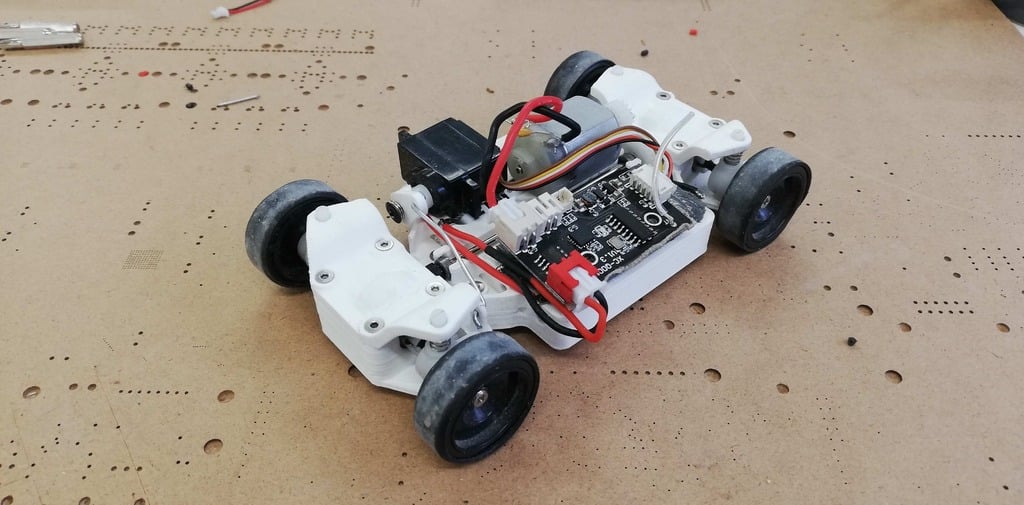

OpenZ - 4WD - 4xAAA (based on TRQ1) (4WD4AAA_V2.3)

thingiverse

This is a 1/28 OpenZ R/C chassis. I recently broke my TRQ1 (mini-Q) chassis and decided to create my own design. It features four-wheel drive and is powered by four AAA batteries. I chose to keep all the functional components from the original TRQ1 and integrate them into a new 3D printed chassis. These components include transmission, differentials, servo, main board, motor, knuckles, axles, and bearings. The dimensions of this design are as follows: - Wheelbase: 93.75 mm - Chassis length: 116.5 mm - Width between wheels: 54.00 mm - Chassis width: 59.30 mm - Total width: 71.00 mm Initially, I identified several issues with the original TRQ1 chassis: - Poor weight distribution due to batteries and motor placement. - Cracking plastic when removing differential covers and electronics plates. - Fragile and clumsy design. - Lack of adjustability in various areas. - Limited steering angle. To address these problems, I've implemented the following changes: - Batteries are now placed underneath the chassis, positioned as low as possible. They can be accessed from the underside. - AAA plate contacts purchased on Amazon secure the batteries in place. - Plastic screws have been replaced with M2x16 countersunk screws and M2 nuts for added stability. The new design significantly improves stiffness and steering angle. Following extensive testing, I confirmed that weight distribution is now evenly balanced. The increased steering angle also enhances drifting performance. Please view my YouTube videos showcasing this prototype: https://www.youtube.com/watch?v=p_maU1PrFMQ https://www.youtube.com/watch?v=e4zUvdRYPdo&t=1s This 3D printed chassis was created without supports, using PLA with a layer thickness of 0.3 mm. Currently, the electronics are not fully integrated; they're placed over the chassis using hot glue and double-sided tape. The receiver and ESC are positioned in the same spot as on the original TRQ1, secured with hot glue. - The servo is mounted on the right side, oriented similarly to its placement on the TRQ1. It's held in place with double-sided tape. - The motor is situated at the back of the chassis between two plastic ridges. Additional layers can be added beneath the motor for optimal alignment. Future updates will include: - Creating brackets and mounting points for electronics - Adding adjustable motor placement for varying gear ratios - Incorporating camber and toe adjustments Please note that some images are from earlier prototype iterations. For those interested, I've shared a 1967 Ford Mustang shell design on Thingiverse: https://www.thingiverse.com/thing:4281093 I'll be sharing updates soon with an improved version of this chassis design.

With this file you will be able to print OpenZ - 4WD - 4xAAA (based on TRQ1) (4WD4AAA_V2.3) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on OpenZ - 4WD - 4xAAA (based on TRQ1) (4WD4AAA_V2.3).