Office Plasma Cutter

thingiverse

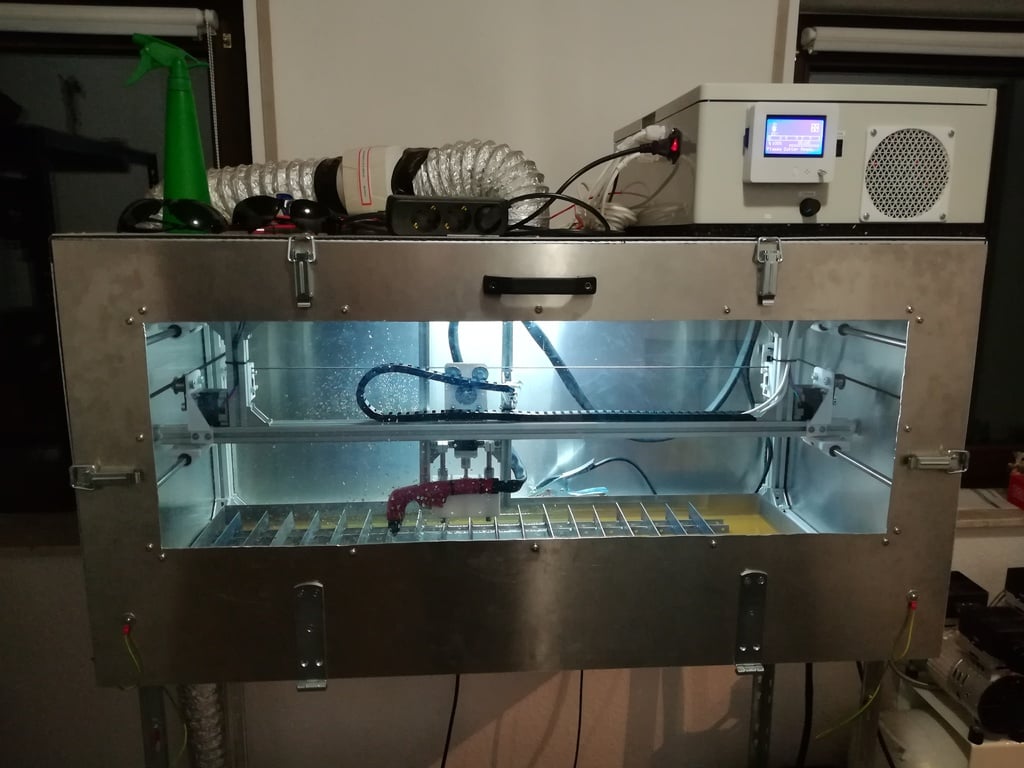

It seems like you have provided a detailed list of components and tools required for building a CNC plasma cutter. This is an impressive project that requires careful planning, precise execution, and attention to safety. Here's a breakdown of the components and tools listed: 1. **Linear Rod Holder**: A set of linear rod holders are required to hold the rods in place. 2. **Linear Rods**: Two Ø10mm linear rods are needed for the x-axis and y-axis. 3. **Leadscrew and Nut**: A T8 leadscrew and nut are used for precise movement along the z-axis. 4. **Motor Jaw Shaft Coupler**: A coupler is required to connect the motor to the leadscrew. 5. **LMH10UU Bearings**: Two LMH10UU bearings are needed for smooth movement of the x-axis and y-axis. 6. **Screws, Nuts, and T-nuts**: Various screws, nuts, and t-nuts are required for assembly. **Water Table Components** 1. **Stainless Steel Tub**: A stainless steel tub is used as the base of the water table. 2. **Galvanized Sheet Metal**: Nineteen pieces of galvanized sheet metal are needed to create the water table's frame. 3. **U-Profile**: Two U-profiles are required for additional support. **Electronics Components** 1. **Display Case**: A display case is used to house the electronics. 2. **Fan Grill**: A fan grill is mounted on the display case for ventilation. 3. **IEC Socket, Fuse, and Switch**: An IEC socket, fuse, and switch are required for power supply management. 4. **LED Lamp**: A LED lamp is used for illumination. 5. **ReprapDiscount Full Graphic Smart Controller**: This controller is the brain of the CNC machine. 6. **RAMPS 1.4**: The RAMPS 1.4 board is a popular choice for CNC machines. 7. **Stepper Drivers**: Three Nema 23 stepper drivers and one Nema 17 stepper driver are required for precise movement. 8. **Relais Module**: A relais module is used to control the plasma trigger switch. 9. **DC Motor Speed Controller**: This controller is used to regulate the speed of the DC motor. 10. **Power Supply**: A power supply unit (PSU) is required to power the electronics. 11. **DC-DC Converters**: Two DC-DC converters are needed for converting voltages. **Tools and Safety Equipment** 1. **Air Compressor**: An air compressor is necessary for operating the plasma cutter. 2. **Plasma Cutter**: A plasma cutter with a pilot arc function is required for precise cutting. 3. **Window or Ventilation**: Good ventilation is essential to prevent inhalation of fumes and particles. 4. **Fire Extinguisher**: A fire extinguisher should be kept nearby in case of emergencies. 5. **Towel**: A towel is useful for cleaning up spills. **Software** 1. **Marlin Setup**: The Marlin setup file is uploaded to the RAMPS 1.4/Arduino Mega board for operation. 2. **Inkscape and Fusion 360**: These design software are used for creating drawings and models. 3. **Estlcam**: Estlcam is a CAM software used for generating cutting paths. **Setup and Operation** 1. The Marlin setup file is uploaded to the RAMPS 1.4/Arduino Mega board via the Arduino IDE. 2. Inkscape and Fusion 360 are used to create drawings and models, which are then exported as .svg files. 3. Estlcam is used to generate cutting paths from the .svg files. 4. The .gcode file is loaded onto an SD card or uploaded directly to the ReprapDiscount Full Graphic Smart Controller. 5. The plasma cutter is set up and the compressor is turned on. 6. The ventilation system is activated, and the plasma trigger switch is engaged. 7. The CNC machine is started, and the file is executed. It's recommended to keep the door open when not in use to prevent moisture buildup and potentially hazardous hydrogen gas formation when cutting aluminum.

With this file you will be able to print Office Plasma Cutter with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Office Plasma Cutter.