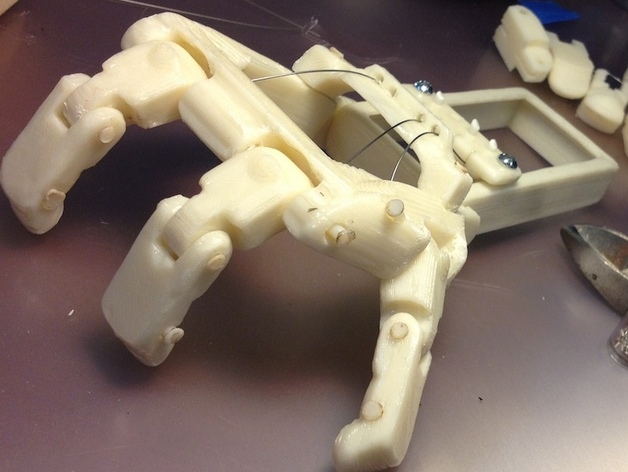

Ody Hand RP 1.0 (a Prosthetic Hand Research Platform)

thingiverse

The Ody Hand RP 1.0 is a Research Platform to be used by e-NABLE R & D teams for the development of prosthetic hands for children born without fingers. For more information or to get involved, visit http://enablingthefuture.org/. The Ody Hand was chosen as a research platform because (1) it is recognized and understood within the e-NABLE community and (2) it has simplicity that allows for very rapid prototyping for iterative design and experimenting. Instructions Experiment 1: Proof of concept for using 3mm printing filament for hinge pins and for wire attachment posts. The Ody Hand RP 1.0 modifies the original Ody Hand design for the purpose of easy printing and assembly while eliminating features for attaching the hand to a user. Changes include the use of 3mm 3D printing filament for hinge pins. The ends of the pins are melted into buttons with a soldering gun in order to keep them from being removed. When the pins need to be removed to iterate the design, the buttons can be clipped off, ground off or drilled out. A 3Doodler hand-held 3D printer also works well for retaining the hinge pins by adding blobs on each end of the pins. 3mm filament was also used as attachment posts for the wire ends. In the finger tips, the wire channel is sized to accommodate the wire loop, and on the forearm there are holes to accommodate short pieces of 3mm filament which can be held in place with blobs on the underside created with a 3Doodler in the manner of a glue gun. Results: Advantages of using 3mm filament rather than printed pins include strength of the pins (especially when used as posts with cross grain) and the requirement to use slower, higher resolution settings on the printer to get good quality pins. Experiment 2: Proof of concept for using .5mm music wire as a flexor/extensor mechanism. Ody Hand RP 1.0 demonstrates the proof-of-concept for using .5mm music wire as a flexor/extensor mechanism in a prosthetic hand in place of the plastic filament used in the normal Ody Hand. The wire flexor/extensor mechanism is for research purposes only, and it should not be used on a prosthetic (especially in devices for children) until considerable research has been done on any potential failure modes where a pointed end of the wire may be exposed. The Ody Hand RP 1.0 design attempts to address the safety concern by the design of (1) the termination created on the ends of the wire, (2) the method by which the wire is attached to the device. The loop termination was created by bending the tip of the wire with (preferably rounded) needle-nosed pliers and crimping the loop with little aluminum beads. A specialty crimping device that can be obtained at a hobby shop or fabric shop and it is recommended that 2 beads be crimped on each loop for extra safety against their coming loose. Results: The push/pull wire tendons showed some deformation during the pushing, especially in the thumb. The slack thus created will require extra wrist displacement, but It is not known whether this presents a problem. Specific prosthetic devices may be able to take advantage of the low friction of the wire by using channels or tubes to guide the wire like the cable on a bicycle hand break. Later experiments will evaluate pros and cons of wire use by taking physical measurements of forces on the platform.

With this file you will be able to print Ody Hand RP 1.0 (a Prosthetic Hand Research Platform) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ody Hand RP 1.0 (a Prosthetic Hand Research Platform).