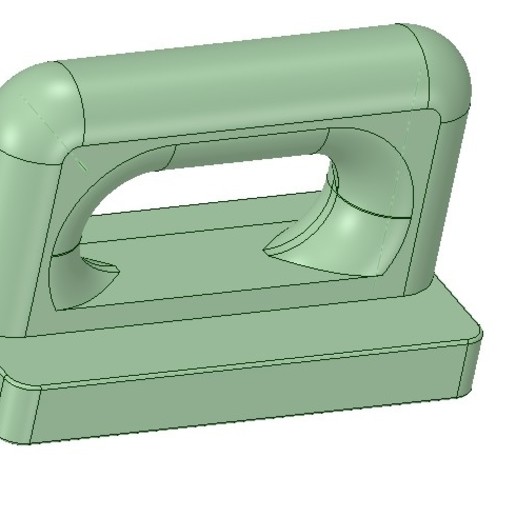

Nylon Internal Flat Slide and Slug ABA91 3d-print

cults3d

Nylon Internal Flat Slide and Slug ABA91 3d-print High-quality 3d model of Nylon Internal Flat Slide If you’re looking for a way to make raising and lowering your mainsail a breeze, then you might want to look into installing sail slugs or slides on your sail. These small but mighty components allow the sail to move easily inside the track and stack on the boom in the mast slot. Not only does this help prevent the sail from catching wind and coming out of the bottom of the mast slot, but it also helps reduce wear and tear on your sail. This selection includes external sail slides, internal sail slides, and slugs to help you complete the job. Slugs are small barrels, often made of nylon that are secured ahead of the boltrope and then inserted into a slot on the mast instead of the rope. Slides are similar but feature a small, T-shaped design to allow for easy installation in a mast slot. External slides attach to a track on the outside of the mast. One thing to note is that if you need to replace parts but can’t find the proper match, you will really need to replace all of the components. This is because your sail won’t function properly if the hardware has a different amount of space between it and the sail. Choosing the appropriate slug and slide really comes down to sizing and personal preference. When sizing, the primary goal is to ensure that your slugs and slides properly fit the mainsail slot on your boat. Once you’ve determined the appropriate sizing, you can pick styles that help you maximize sail performance. For example, if your sail has full battens, you’ll want to choose a style that will help distribute batten pressure in order to prevent jamming. Use when printing TiTi Hard (TPU D70) Total PA GF30 NYLON 12, NYLON Carbon, NYLON Carbon 2 ATTN -------------nylon------------------------------------------------ Keep the nylon dry Drying Nylon Filament - Simply place the coil in the oven at about 60 ° C for 5-6 hours. Of course, keep an eye out. The extrusion temperature of nylon should be 240-260 ° C and above. The work surface should be heated to approximately 100+ ° C. Recommend even 100 ° C and more, because nylon is sensitive to too fast cooling, from which it warps. To help grip on a metal or glass desktop, use glue Make sure the layer cooling fans are turned off, and the printing process itself is not drafted. Place the details on the table when printing, look at the photo The model is made with much attention to details. All real sizes you can see in the photos. Everything can be seen in the photo. The model can be printed as a 3D model, as well as produced on CNC machines. Made in SpaceClaim, tested in the manufacture of the master model of the product. This is a fully solid-state version for 3d-print, this is not a scan version. At the photos you can see the contours of the models on screens with STL or OBJ files, it is enough to understand the possibility of printing a model or producing a model by a CNC machine It is possible to model anyone another model according to your size or drawings and sketches. ATTENTION! This item is a DIGITAL 3D model (*STL *OBJ file format) for ArtCAM, Aspire, CUT3D, Cura any software applications for CNC and 3D printers. Its files For CNC Routers and 3D printers. Not a Vectric, not a bitmap file, not a G-code. You buy a digital model image file for the manufacture of the product, and not the product itself as a physical unit of goods made of glass or wood. Non-commercial use only. Attribution-NonCommercial CC BY-NC

With this file you will be able to print Nylon Internal Flat Slide and Slug ABA91 3d-print with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nylon Internal Flat Slide and Slug ABA91 3d-print.