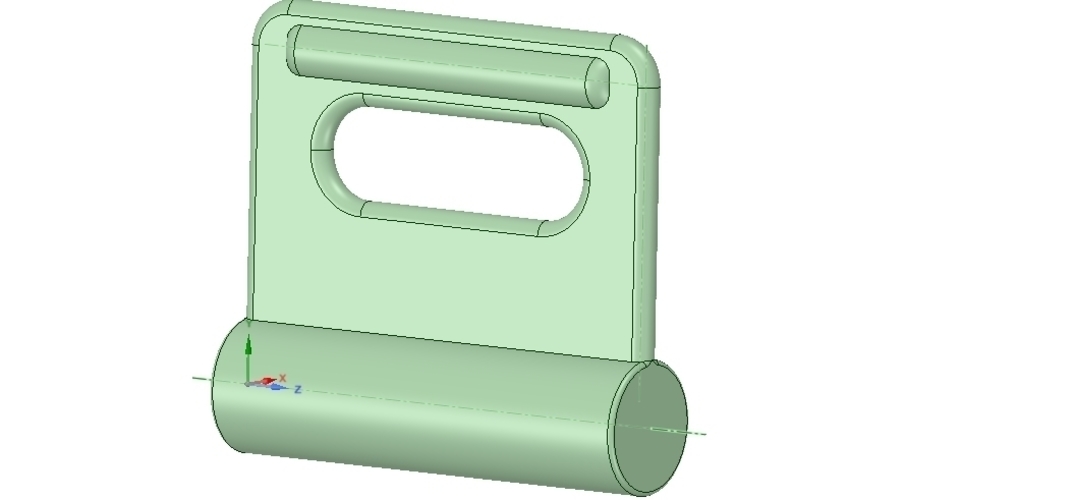

Nylon Internal Flat Slide and Slug ABA-258-01 3d-print

pinshape

Quality 3D Model Nylon Internal Flat Slide Are you looking for a way to make your sail's hoisting and lowering easy? You may need to install a grommet or slide on your sail. These small but powerful components allow the sail to move easily inside the track and fold onto the boom in the mast's recesses. This not only prevents the sail from being caught by the wind and coming out of the lower part of the recess, but also reduces sail wear. This option includes external sail blocks, internal sail blocks, and slides to help you complete your project. Slides are small containers, often made of nylon, that are attached to the bolt rope and then inserted into the mast's recess instead of a rope. They are similar to blocks but have a small T-shaped construction that makes them easier to install in the mast track slot. External slides are attached to the guide outside the mast. Note that if you need to replace parts but can't find a suitable match, you really need to replace all components. This is because your sail will not function properly if there is different space between the equipment and the sail. Choosing the right block and slide ultimately comes down to size and personal preference. When determining sizes, the main goal is for your slides and blocks to fit correctly in the groove of the sail on your boat. After you've determined the correct size, you can choose styles that will help increase sail performance. For example, if your sail has full battens, you need to select a style that helps distribute batten pressure to prevent jamming. Use for printing TiTi Hard (TPU D70) Total PA GF30 NYLON 12, NYLON Carbon, NYLON Carbon 2 WARNING ------------- nylon ----------------------------------- ------------- Keep the nylon dry (drying nylon thread - simply place the spool in the oven at around 60 ° C for 5-6 hours. Of course, keep an eye on it.) Temperature of nylon extrusion must be at least 240-260 ° C and above , The working surface should be heated to about 100+ ° C. It is recommended to even 100 ° C or more, as nylon is sensitive to too rapid cooling, which causes deformation. To help capture a metal or glass worktable, use adhesive Make sure the ventilation layers' fans are off and the printing process is not assembled. -------------------------------------------------- ---------------------- When printing, place parts on the table, look at the photos The model was made with great attention to detail. All real sizes can be seen in the photos. Everything can be seen in the photos. The model can be printed as a 3D model and also manufactured on CNC machines. Made in space, tested during manufacturing of the master model of the product. This is a fully solid version for 3D printing, it's not a scanning version. On the photos you can see contours of models on screens with stl or obj files, enough to understand the possibility of printing a model or making a model on a CNC machine. You can model any other model of your size or by drawings and sketches. WARNING! This element is a DIGITAL 3D model (file format * STL * OBJ) for ARTCAM, ASPIRE, CUT3D, Cura Any software applications for CNC machines and 3D printers. Its files are for CNC machines and 3D printers. Not vector, not raster file, not G-code. You buy a digital model image file to make a product, not the physical unit of the product made of glass or wood. Only for non-commercial use.

With this file you will be able to print Nylon Internal Flat Slide and Slug ABA-258-01 3d-print with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nylon Internal Flat Slide and Slug ABA-258-01 3d-print.