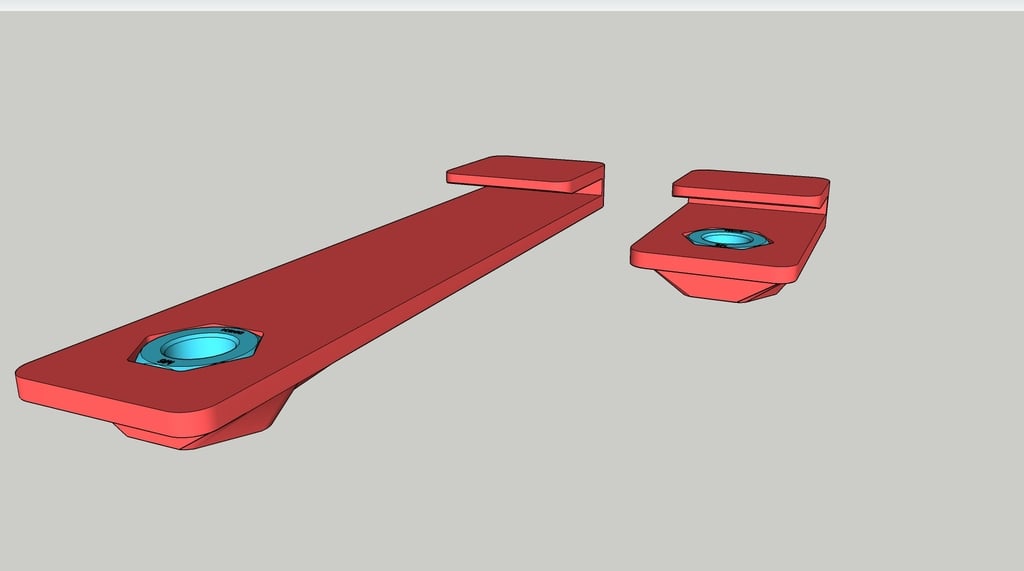

Nut Bracket for German RepRap X400‘s Built-Table adjustment

thingiverse

As the X400’s built table adjustment is not really a joy, these two simple things make operator's lives much easier. The original printer setup requires two tools at the same time for the table's Z-adjustment. Above the table an Allen wrench key must be used to turn the self-locking nut on the bottom side of the metal plate, which holds it in place while adjusting the Allen screw. Each time the adjustment is changed, the nozzle/table distance must be checked afterwards. One can imagine that this takes a lot of time for all four adjustment points. These brackets replace the ring-wrench and can be simply installed by shifting them on the metal plate. No printer modification is necessary. After installation, the only tool to be used is the Allen key, which also allows the distance check during adjustment. This will save a lot of time! Installation hint: 1. Unscrew the self-locking nut (take care not to pull out the Allen screw completely!) 2. Remove the washer between nut and metal plate 3. Insert nut into the bracket 4. Shift bracket in its correct position until you can screw in the Allen screw. 5. Re-Adjust the table by only using the Allen key Print out each part two times. The long brackets are for the rear left- and right side. The short brackets fit from the front side. Material recommendation: Due to a durable material stability, I recommend to use ABS or CPE or equivalent material.

With this file you will be able to print Nut Bracket for German RepRap X400‘s Built-Table adjustment with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nut Bracket for German RepRap X400‘s Built-Table adjustment.